If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsMicro Differential Pressure Transmitter – PN53

The PN53 series micro differential pressure transmitter adopts a thermal-type low-pressure sensor core. It utilizes a micro-flow channel integrated into the sensor chip to detect airflow changes and determine air pressure.

PN53 features strong overload capacity, excellent electromagnetic interference resistance, wide measuring range, and multiple signal outputs. It is widely used for measuring air or neutral gases in systems such as HVAC, process control, environmental monitoring, clean rooms, and other applications requiring micro differential pressure detection.

Sensor Core: Imported thermal low-pressure sensor core with sensitive pressure response

Stability & Repeatability: High stability, excellent repeatability

Installation: Easy to install, insensitive to installation orientation

EMI Resistance: High immunity to electrical interference; optional isolated output

|

Working Medium① |

Air or neutral gases |

|

|

Measurement Range |

±25Pa, ± 50Pa, ± 100Pa |

|

|

Overload Pressure |

2Bar |

|

|

Accuracy |

±25Pa±1Pa |

|

|

|

± 50Pa±1%F.S |

|

|

|

± 100Pa±0.5%F.S |

|

|

Operating Temperature |

-20℃ ~70℃ |

|

|

Storage Temperature |

-40℃ ~80℃ |

|

|

Temperature Drift |

0.03%FS/℃ |

|

|

Ingress Protection |

IP65 |

|

|

Electrical Connection |

4-wire |

6-wire |

|

Output Signal |

RS-485 |

4~20mA/0~10VDC |

|

Metal barbed fitting, Ø6.2 mm |

9-30VDC/24VAC±20% |

12-30VDC/24VAC±20% |

|

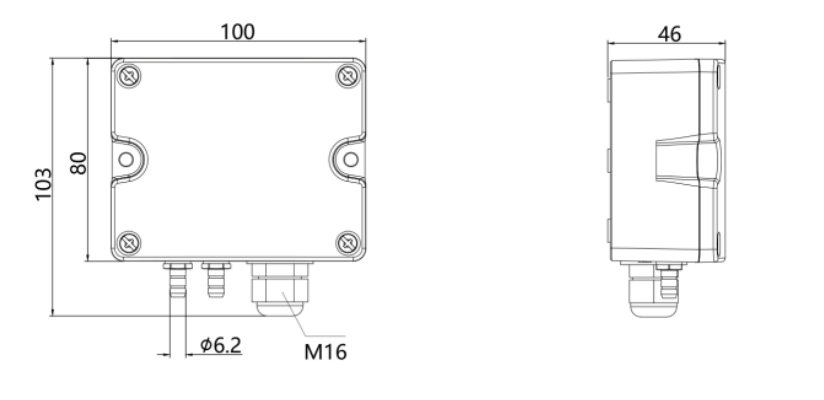

Pressure Port |

Metal barbed fitting, Ø6.2 mm |

|

|

Communication |

RS-485 standard interface, Modbus RTU protocol |

|

|

Certifications |

RoHS compliant, CE certified (EU) |

|

|

EMC Compliance |

EN61326-1 |

|

|

Measurement media include air, oxygen (O₂), nitrogen (N₂), argon (Ar), and carbon dioxide (CO₂). For other gases, please contact the supplier. |

||

|

PN53- |

1 |

N |

A |

Detailed |

|

PN53- |

|

|

|

PN53 Series Micro Differential Pressure Transmitter |

|

|

1 |

|

|

-25 ~25Pa |

|

|

2 |

|

|

-50 ~50Pa |

|

|

3 |

|

|

-100~ 100Pa |

|

|

|

N |

|

Without display |

|

|

|

O |

|

With display |

|

|

|

|

A |

4-20mA and 0-10VDC (simultaneous output) |

|

|

|

|

E |

RS-485 communication |

|

|

|

|

E1 |

RS-485 with isolation |

|

Note: The selection guide is for parameter selection only. Final product configuration is defined by corresponding factory code. |

||||

The pressure sensing core is calibrated at a reference absolute pressure of 1Bar (100,000Pa). As the sensor uses a thermal principle, altitude/atmospheric pressure variations affect output. Use the following formula to compensate:

ΔPeff = ΔPsensor × (100,000Pa / Pabs)

Where:

ΔPeff = compensated micro pressure difference

ΔPsensor = current output from the sensor

Pabs = absolute pressure at installation location (i.e., local atmospheric pressure in Pa)

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Micro Differential Pressure Transmitter – PN53 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Micro Differential Pressure Transmitter – PN53 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Micro Differential Pressure Transmitter – PN53 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .