If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsDigital Display Pressure Transmitter Controller – PN53E

Working Principle and Features:

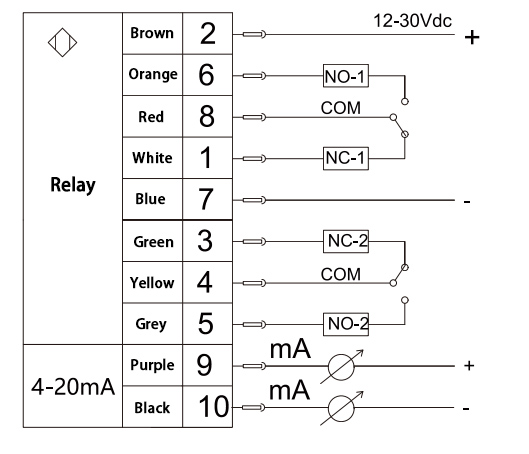

The PN53E pressure monitoring and control device integrates key functionalities including one analog current output, two relay switch outputs, and local digital display.

Designed with SMT technology and an integrated design philosophy, it supports constant voltage and constant current excitation for sensors, making it compatible with diffused silicon, ceramic, and strain gauge-type pressure sensors.

The built-in microprocessor enables configuration via three keys for adjusting zero point, full scale, decimal point, display rate, control points, and current output—without the need for any potentiometer adjustments. The entire device is designed for industrial-grade temperature environments and offers strong anti-interference capabilities.

Key Features:

Equipped with a high-brightness 0.4-inch digital LED display

Fully intelligent operation, supports user calibration and non-linear correction of display values

Ultra-low temperature drift, suitable for use in -40°C to +85°C industrial environments

Highly flexible switch point settings with automatic control direction recognition and hysteresis insertion

Outperforms similar products in specifications, with excellent electromagnetic interference resistance

Supports dynamic switching between three user-defined pressure units

Data acquisition resolution: 16-bit binary

Display type: 0.4-inch LED (red)

Display range: -1999 ~ 9999

Temperature drift: < 60ppm

Switch setting range: -1999 ~ 9999, automatic hysteresis, automatic control direction change

Power supply: 8–32VDC

Current output resolution: approx. 0.001mA

Operating temperature: -40℃ ~ +85℃

Sampling rate: adjustable, max 10 times/sec, min 1.8 times/sec

Accuracy: 0.1%

Sensor excitation: Constant current 0.1–0.5mA, constant voltage 3VDC / 5mA

|

PN53E- |

Z |

A |

G4 |

D |

A |

Q |

Z |

1 |

Detailed |

|

PN53E- |

|

|

|

|

|

|

|

|

PN53E Series Electronic Digital Pressure Switch Transmitter |

|

|

Z |

|

|

|

|

|

|

|

Positive pressure |

|

|

F |

|

|

|

|

|

|

|

Negative pressure |

|

|

|

A |

|

|

|

|

|

|

Pressure Ranges :-1…1 bar or 0…1 bar |

|

|

|

B |

|

|

|

|

|

|

Pressure Ranges :-1…2 bar or 0…2 bar |

|

|

|

C |

|

|

|

|

|

|

Pressure Ranges :-1…5 bar or 0…5 bar |

|

|

|

D |

|

|

|

|

|

|

Pressure Ranges :0.. 10bar |

|

|

|

E |

|

|

|

|

|

|

Pressure Ranges :0..25bar |

|

|

|

F |

|

|

|

|

|

|

Pressure Ranges :0.. 100bar |

|

|

|

G |

|

|

|

|

|

|

Pressure Ranges :0.. 160bar |

|

|

|

H |

|

|

|

|

|

|

Pressure Ranges :0..250bar |

|

|

|

I |

|

|

|

|

|

|

Pressure Ranges :0..400bar |

|

|

|

J |

|

|

|

|

|

|

Pressure Ranges :0..600bar |

|

|

|

K |

|

|

|

|

|

|

Custom range (e.g., 300 bar) |

|

|

|

|

G4 |

|

|

|

|

|

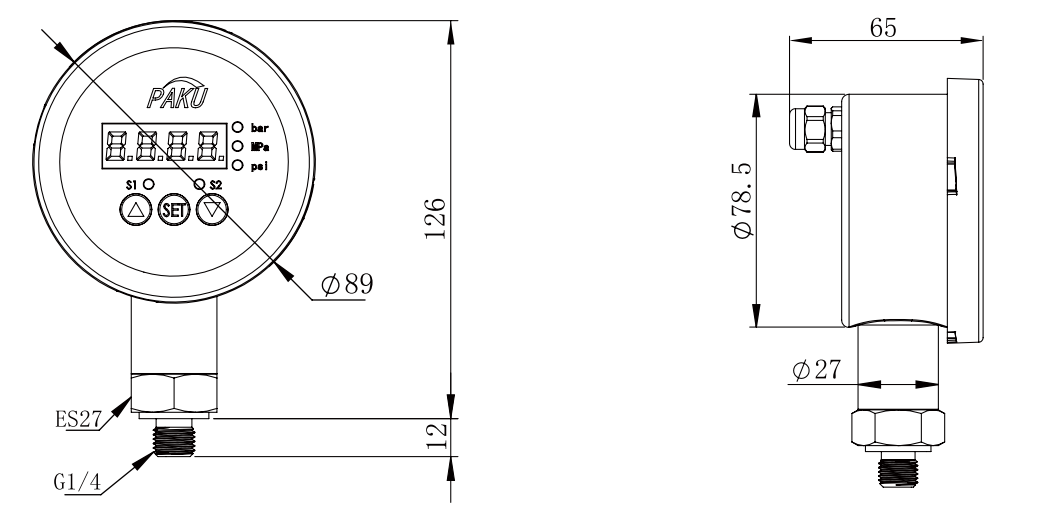

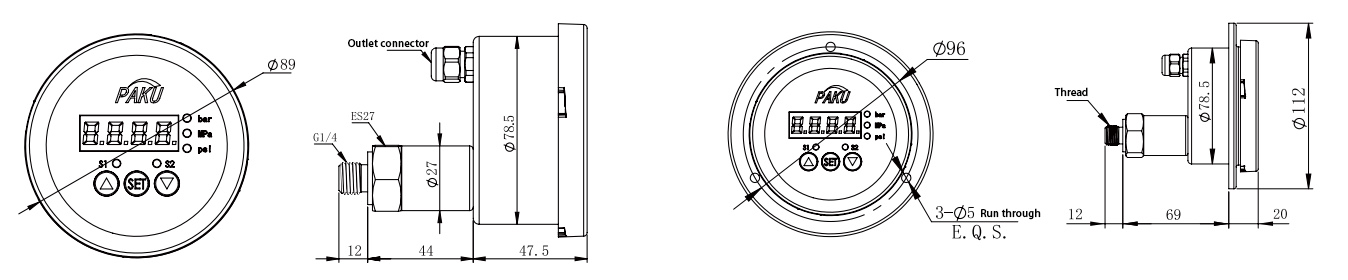

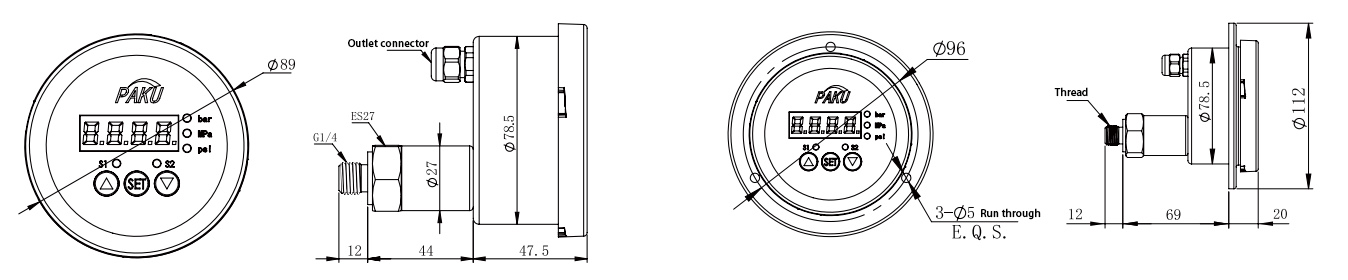

G1/4 thread |

|

|

|

|

G2 |

|

|

|

|

|

G1/2 thread |

|

|

|

|

K5 |

|

|

|

|

|

Clamp connection (Ø50.5 mm, max 16 bar) |

|

|

|

|

P |

|

|

|

|

|

Flush diaphragm connection |

|

|

|

|

|

D |

|

|

|

|

Custom thread |

|

|

|

|

|

H |

|

|

|

|

External thread |

|

|

|

|

|

K |

|

|

|

|

Internal thread |

|

|

|

|

|

|

A |

|

|

|

2 relay outputs |

|

|

|

|

|

|

B |

|

|

|

2 relay outputs + 4–20mA analog output |

|

|

|

|

|

|

|

Q |

|

|

Direct cable output |

|

|

|

|

|

|

|

|

Z |

|

Damping screw (optional) |

|

|

|

|

|

|

|

|

S |

|

Heat sink (optional) |

|

|

|

|

|

|

|

|

|

1 |

Axial |

|

|

|

|

|

|

|

|

|

2 |

Radial |

|

|

|

|

|

|

|

|

|

3 |

Axial flange type |

|

For 316L stainless steel housing, please specify when ordering. The selection guide is for reference only. Final product configuration is based on code assigned at the factory. |

|||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Digital Display Pressure Transmitter Controller – PN53E Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Digital Display Pressure Transmitter Controller – PN53E Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Digital Display Pressure Transmitter Controller – PN53E Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .