If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsMetal Electronic Flow Switch-SN11

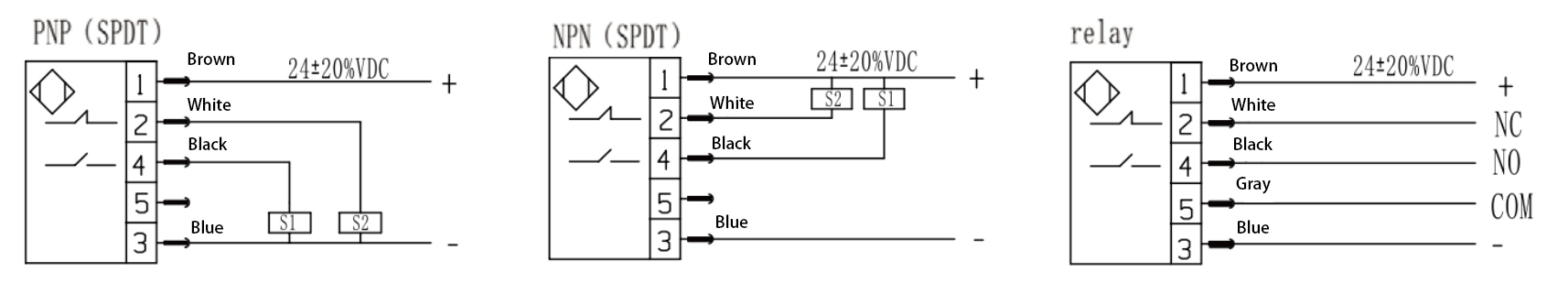

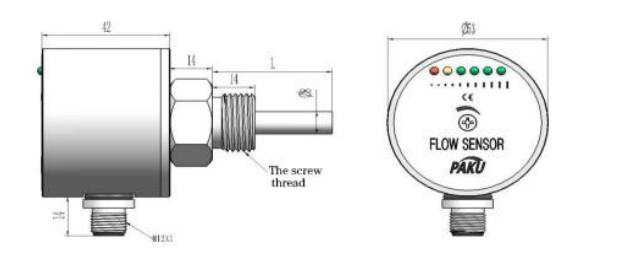

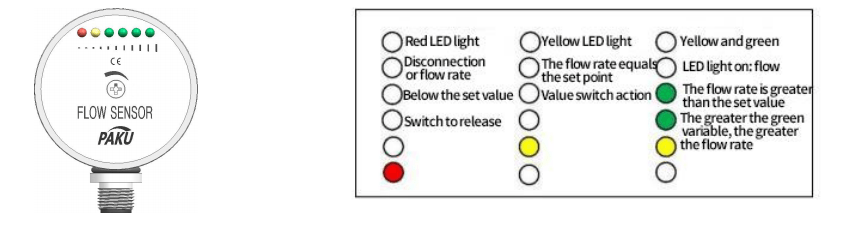

Based on the thermal principle, the sealed probe contains two resistors, one of which is heated to act as a detection resistor and the other unheated to act as a reference resistor. As the medium flows, the heat is removed from the heated resistor and the resistance value is altered, with the difference between the two resistances being used as a basis for determining the flow rate. No moving parts, maintenance-free, easy to install, one model for a variety of pipe diameter requirements, switching volume continuously adjustable, very low pressure loss, compact structure, LED display flow trend and switching status.

Pneumatic and hydraulic dual purpose, low flow rate alarm, can be used for pneumatic and hydraulic systems, can be used for circulating water, cutting fluid and lubricating oil cut-off detection, and pump idling protection.

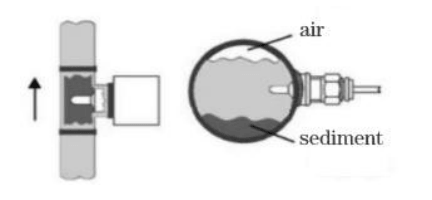

For vertical installation, it should be installed on the pipe section flowing from bottom to top.

When mounted horizontally, the probe should be kept away from air and sediment.

| SN11- | G2H | A | 3 | 1 | X | A | 30 | specification | ||||||

| SN11- | SN11 series electronic flow switch | |||||||||||||

| M1K | Interface thread M18*1.5 internal thread With the installation accessories, it is convenient to rotate and adjust the installation |

|||||||||||||

| G2H | Interface thread G1/2 female thread | |||||||||||||

| G4H | Interface thread G1/4 male thread | |||||||||||||

| K5 | Chuck interface (outer diameter 50.5mm) | |||||||||||||

| Custom threads, such as NPT1/2, type N12 | ||||||||||||||

| A | DC DC24V±20% power supply | |||||||||||||

| 1 | PNPoutput | |||||||||||||

| 2 | NPNoutput | |||||||||||||

| 3 | relay output | |||||||||||||

| 1 | Normally open + normally closed output | |||||||||||||

| X | Probe material: 304 stainless steel | |||||||||||||

| XL | Probe material: 316L stainless steel | |||||||||||||

| A | Connector type (standard with 2 meters of wire) | |||||||||||||

| B | Straight out | |||||||||||||

| 30 | Probe rod length unit mm (including thread) | |||||||||||||

| L | Customized probe rod length unit mm (including thread) |

|||||||||||||

| * The factory is standard equipped with electrical accessories M12 connector type ZL05-PU02FG * Select M18*1.5 internal thread installation mode, please pay attention to the selection of installation accessories *Customizable thread, H for external thread, K for internal thread * For selection of electrical accessories and installation accessories, please refer to the appendix page on page - * The selection table is only available for parameter selection, and the corresponding code is delivered. |

||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Metal Electronic Flow Switch-SN11 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Metal Electronic Flow Switch-SN11 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Metal Electronic Flow Switch-SN11 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .