If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

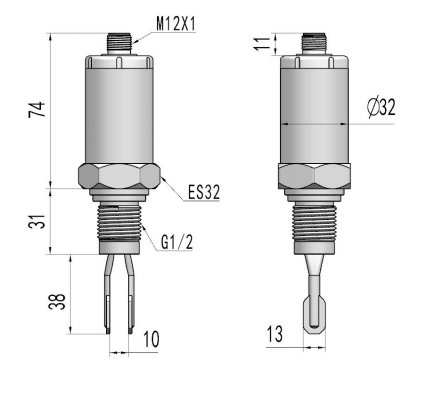

Get couponsCompact tuning fork material (liquid) level switch-LF100B

LF100B series tuning fork type material level limit switch is a kind of universal material level limit switch. Inspired by piezoelectric crystal a tuning fork produces an oscillation, when the tuning fork is liquid or solid immersion vibration frequency change, change the frequency by the electronic circuit electric parameters detected from the media and the turbulent, agitation, bubble, vibration, the influence of such factors as no moving parts, so no maintenance amount adjustment, is the ideal choice of the material level switch under complicated conditions.

- This tuning fork has a self-check function, on the one hand, it is to overcome the phenomenon of vibration absorption after the fork is installed in the barrel wall, on the other hand, it is to prevent noise interference and avoid misoperation.

- The factory set value of the product is the density of water (1g/cm ³), which is used as the benchmark for state switching. When the density of the substance to be tested is greater than or equal to 1g/cm³ , it can be used normally without relearning. When the density of the object to be tested is less than 1g/cm³ , the detection Settings need to be re-conducted.

| supply voltage | 19…60VDC 50/60Hz | |||

| switching time | About 2 seconds when covered with medium, about 3 seconds when no medium |

|||

| environment temperature |

-40…+80℃ | |||

| storage temperature |

-40…+85℃ | |||

| medium temperature |

-40…+150℃ | |||

| operating pressure |

-1…+40bar | |||

| The material being tested |

Powder and particle =10mm, density >0.1g/cm³ |

|||

| Liquid, viscosity =10000mm2/s, density >0.7g/cm³ |

||||

| connection type | G1-N11* | |||

| electrical interface |

M12 x P1.0 connector | |||

| shell material | Stainless steel S304 | |||

| The fork body material Fork material |

Stainless steel S304/ Stainless steel S316 | |||

| output modeOutput |

Relay output, Load DC60V / 4 a |

|||

| Open collector (NPN) output, negative 400mA |

||||

| Open collector (PNP) output, negative 400mA |

||||

| power dissipation | DC power supply 0.25W AC power supply 1.5W |

|||

| LF100B- | A | 3 | S | 1 | B | X | specification | |||||

| LF100B- | LF100B small tuning fork (liquid) level switch |

|||||||||||

| A | The normal temperature models | |||||||||||

| B | High temperature models | |||||||||||

| 1 | PNPoutput | |||||||||||

| 2 | NPNoutput | |||||||||||

| 3 | relay output | |||||||||||

| S | M12 x 1 connector | |||||||||||

| 1 | Power supply: 24V DC | |||||||||||

| A | G1 "female thread connection | |||||||||||

| B | G1/2 female thread connection | |||||||||||

| C | flanged joint | |||||||||||

| X | Fork material: 304 stainless steel | |||||||||||

| XL | Fork material: 316L stainless steel | |||||||||||

| A | Standard tuning fork L=40 mm | |||||||||||

| B | Standard tuning fork L=60 mm | |||||||||||

| C | Standard tuning fork L=100 mm | |||||||||||

| L.. | Extended tuning fork L= mm | |||||||||||

| * The type selection table is only for technical selection, and the corresponding type of the factory model is reflected by the code. |

||||||||||||

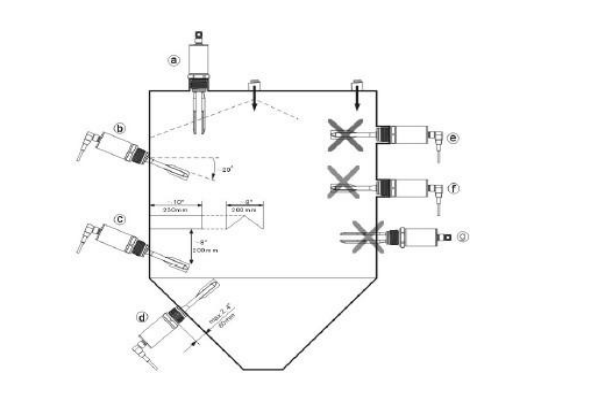

- When installing, the switch can be installed at an Angle of 15-20 degrees horizontally down to reduce the impact of materials and the occurrence of hanging material.

- Installation should be possible away from the tank inlet to avoid material impact and false alarm. If unavoidable, a baffle should be installed between the feed port and the material level.

- The outlet of the terminal box must be facing down, and the fixing nut of the outlet of the power cable must be locked.

- When working in the tank, do not use vibrators to climb or hang any ropes or objects.

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Compact tuning fork material (liquid) level switch-LF100B Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Compact tuning fork material (liquid) level switch-LF100B Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Compact tuning fork material (liquid) level switch-LF100B Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .