If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsElectronic Magnetic Induction Liquid Level Switch Sensor -LF60A

The LF60A Series Compact Static Level Transducer uses an isolated diffused silicon pressure sensor. The liquid level pressure changes the value of the stress measuring element, thereby changing the measuring signal, which is processed by an integrated circuit and converted into an industrial standard electrical signal

output.

-Full metal housing design

-Highlight LED digital display, so that this series of products can be used in various industrial occasions.

-Double key design and user-friendly menu make the product easier to use.

-Multiple connection modes can fully meet various specific installation requirements.

-The display head can rotate 330° to ensure the best viewing Angle under different installation modes.

-for use in non-crystalline media

-can do high precision anti-clogging products, can measure viscous media.

-Teflon coating can be added to meet the requirements of corrosion resistance.

Measurement range: user-defined

Overload pressure: 1.5 times measurement range (1bar=1019.7cm water column)

Measurement medium: corrosive compatible with 304 stainless steel liquid

Pressure: 50bar

Medium density: ≥0.7g/cm³

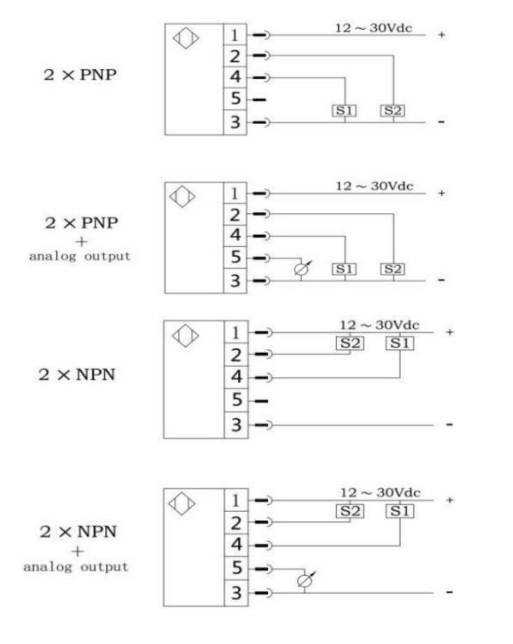

Power supply voltage: 12... 30Vdc

No-load current consumption: maximum 30mA, 24VDC power supply

switched output:Output type: PNP, NPN optional normally open normally closed can be set

S1, S2 output current: <500mA

Response time <10ms

Switch accuracy: ≤ ±0.5% range

Current type analog output: ≤ ±0.5% range

Output type: 4... Can be set to 20 ma

load RA: 0.5 KOhm or less

Linearity: ≤ 0.5% range

Wiring protection: reverse phase, overload, short circuit protection

display:Design: red 4-bit 8mm high brightness LED Display range: 999... 9999

Accuracy: ≤ ±0.5% range

Stability (annual drift) : ≤ ±0.02% range

temperature:

medium temperature:-10...70℃

environment temperature:-35...85℃

storage temperature:-40...125℃

materials:Shell of the watch head: engineering plastic Shell: 304 stainless steel

Medium contact part: 304 stainless steel, Teflon coating (anticorrosive type)

Float: 304 stainless steel

Protection grade: IP67

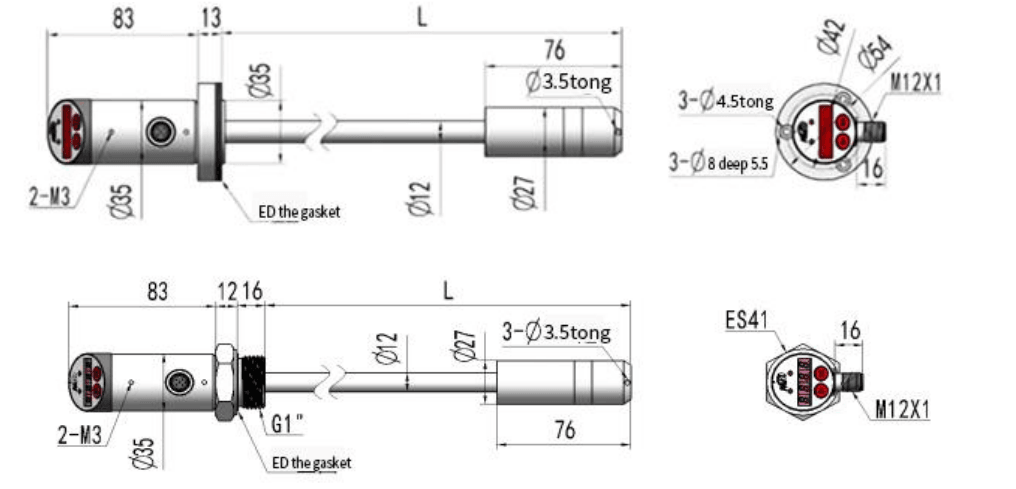

Outgoing way: M12X1 connector

The Flange Type

| LF60A- | A | A | P | A | 1 | 1 | S | L | B | specification | |||

| LF60A- | LF60A series electronic level switch sensor | ||||||||||||

| A | Bar type standard type | ||||||||||||

| B | split type | ||||||||||||

| B.. | Connecting cable length, standard 2m, | ||||||||||||

| Z | Mounting bracket (split type optional) | ||||||||||||

| A | 2 switches output | ||||||||||||

| B | 2 switching quantities +1 analog quantities 4- 20mA output |

||||||||||||

| C | 2 switching quantities +1 analog quantities 1- 5V output |

||||||||||||

| P | PNP output | ||||||||||||

| N | NPN output | ||||||||||||

| A | Thread connection with external thread | ||||||||||||

| B | flanged joint | ||||||||||||

| C | Sanitary chuck connection | ||||||||||||

| 1 | Interface thread: G1 | ||||||||||||

| Custom thread | |||||||||||||

| 1 | Liquid material: 304 stainless steel | ||||||||||||

| 2 | Liquid material: 316L stainless steel | ||||||||||||

| 3 | Liquid material: anti-corrosion | ||||||||||||

| S | M12*1 connector (standard with 2 meters wire) |

||||||||||||

| L | Measuring range: L= mm (unit) | ||||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | |||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Electronic Magnetic Induction Liquid Level Switch Sensor -LF60A Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Electronic Magnetic Induction Liquid Level Switch Sensor -LF60A Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Electronic Magnetic Induction Liquid Level Switch Sensor -LF60A Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .