If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsMaterial (liquid) level switch sensor-LF1000

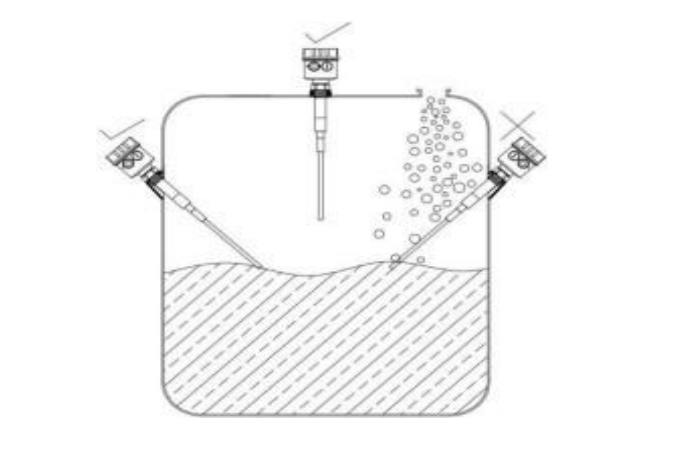

The structure of LF1000 series material (liquid) level switch is divided into two parts: main electrode and compensation electrode. A group of RF signals are applied between the main electrode and the compensating electrode respectively, so it has good adhesion resistance and material hang property. It is a new type of material/liquid level measuring product to replace the capacitor material level switch.

Strong versatility: widely used in the detection of various materials, such as: fly ash, particles, powder, liquid, viscous and other media can be;

High temperature resistance up to 800℃ , pressure up to 5MPa; Can be used for corrosion and impact and other places.

Anti-adhesion: the sensor probe can automatically correct the hanging material in the measurement process, without regular cleaning, which can avoid the occurrence of false measurement and false signal.

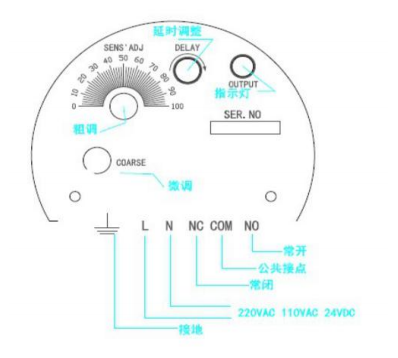

High reliability: the output contact capacity is large, the indicator light shows the working status, the switch has a built-in delay setting to eliminate the influence of medium fluctuation on the measurement of false positives, high stability, long service life.

Mainly used in: chemical industry, oil field, paper making, pharmaceutical, power plant, metallurgy, cement, water and sewage treatment and other industries.

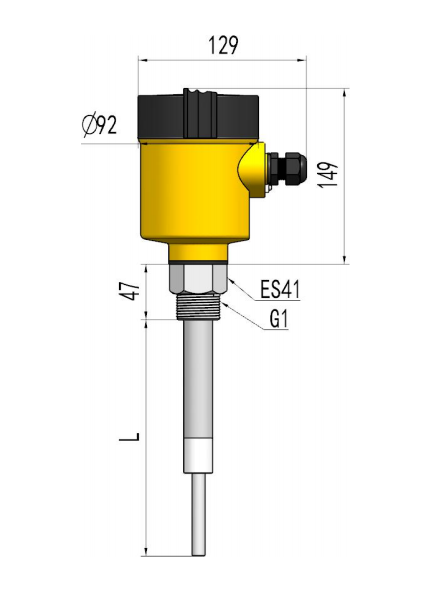

-Measuring range: 0.01~3m (rod type), 0.5~35m (cable type)

-Medium temperature: -200... 800℃ Ambient temperature: -40...80 ℃

-supply voltage:AC220V/DC24V

-Signal output: relay SPDT (NO+NC)

-contact capacity:AC220V5A/DC24V5A

-Delay Settings: 0... Adjustable 30 s

-Sensitivity: 0.5pF, ±0.05pF/10℃

-Loss of power protection: high and low mode, adjustable on site

-Protection grade: IP65, metal case, flameproof EXDIICT5

-Installation: Thread type: 1"NPT outer teeth (can be customized) Flange type: DN25 (customizable)

| LF1000- | 1 | R | A | N1 | D | X | G | 100 | specification | |||

| LF1000- | LF1000 Series Level Switch Sensor | |||||||||||

| 1 | no display | |||||||||||

| 2 | digital display | |||||||||||

| R | 0.01 ~ 3 m pole | |||||||||||

| C | 00.5 ~ 35 m cable type | |||||||||||

| A | PNPoutput | |||||||||||

| B | NPNoutput | |||||||||||

| C | relay output | |||||||||||

| D | 4-20mAoutput | |||||||||||

| N1 | External thread 1 "NPT | |||||||||||

| D | DN25 flange | |||||||||||

| Custom thread | ||||||||||||

| D | DC24V (4-20mA output type only) | |||||||||||

| J | AC220V | |||||||||||

| X | 304SUS | |||||||||||

| S | 316LSUS | |||||||||||

| P | PTFE | |||||||||||

| G | 80℃ | |||||||||||

| Z | 200℃( Install radiator ) | |||||||||||

| D | 400...800℃( Install radiator ) | |||||||||||

| 100 | L=100mm | |||||||||||

| 300 | L=300mm | |||||||||||

| XXX | 0.01... 35m can be arbitrarily selected | |||||||||||

| * The type selection table is only for technical selection, and the corresponding type of the factory model is reflected by the code. | ||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Material (liquid) level switch sensor-LF1000 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Material (liquid) level switch sensor-LF1000 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Material (liquid) level switch sensor-LF1000 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .