If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsTuning Fork Resonance Density Meter (Concentration Meter) - LF100C

Insertion-type Design

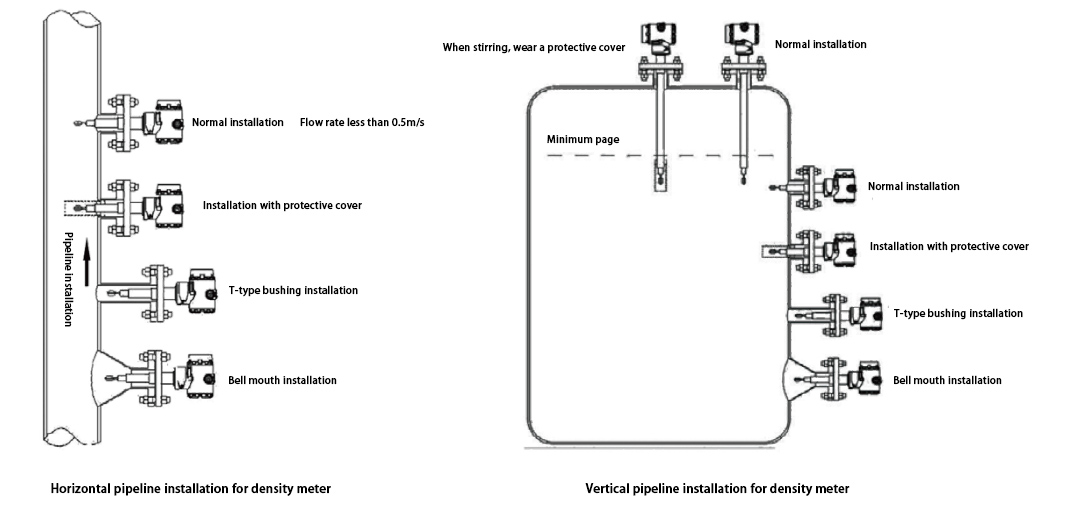

The insertion-type density (concentration) meter is installed by direct insertion, making it widely applicable for media density measurement in pipelines, open tanks, and closed containers. The fluid density is directly determined by the vibration frequency of the tuning fork immersed in the medium. A built-in temperature sensor provides temperature compensation.

Application Scope

The insertion-type density (concentration) meter performs real-time online density measurements. It is suitable for process control where density is the key parameter or for quality control based on solid content percentage or concentration percentage. Typical industries include:

Petrochemical

Brewing

Food processing

Pharmaceuticals

Mineral processing (e.g., clay, carbonate, silicate, etc.)

Specific applications include:

Interface detection in multi-product pipelines

Density measurement of stirred mixtures

Endpoint monitoring in reaction vessels

Interface detection in separators

The sensor operates based on a vibrating element principle. The sensing part is the immersed tuning fork. Vibration is excited by a piezoelectric device fixed at one end of the fork, while vibration frequency is detected by a secondary piezoelectric device at the other end. The circuit at the top amplifies the signal.

The vibration frequency varies with the density of the liquid. Thus, the liquid density can be accurately calculated using the following formula:

D= K0+K1T+K2T2

Where:

D = Uncalibrated density of the measured medium (kg/m³)

T = Vibration period (μs)

K0, K1, K2 = Calibration constants

|

Measurement Range |

0 –2.5 g /cc (0 –2500 kg/m3) ,0~ 100.0% |

|

Calibration Range |

0 –2.5 g /cc (0 –2500 kg/m3) ,0~ 100.0% |

|

Measurement Accuracy |

± 0.001g /cc ( ± 1kg/m3) , ±0.5% |

|

Repeatability |

± 0.001 g /cc ( ± 0. 1kg/m3) ±0. 1% |

|

Operating Temperature Range |

-50℃ ~ + 150℃ |

|

Maximum Working Pressure |

4mpa |

|

Fluid Viscosity Range |

0 –2000 cP |

|

Temperature Coefficient |

Less than 0.1 kg/m³/°C (±0.5% after calibration) |

|

Pressure Influence |

Negligible |

|

Built-in Temperature Sensor |

Digital sensor with temperature compensation |

|

Wetted Materials |

316L, 2205, 2507 stainless steel, Hastelloy C, Titanium, PTFE/PFA |

|

Fork Coating |

Standard: PTFE or PFA |

|

Power Supply |

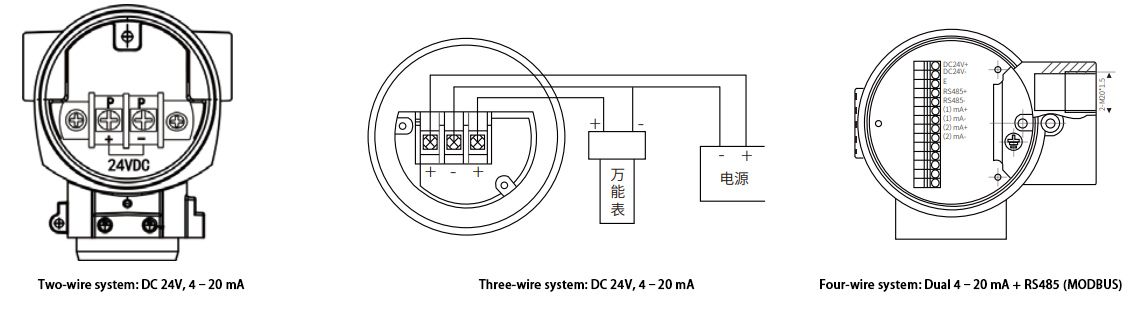

24VDC, ≥50 mA |

|

Analog Output |

4 -20 mA ,0-1000Hz, RS485 Modbus RTU HART |

|

Output Accuracy (at 20°C) |

±0.1% of reading or ±0.05% of full scale |

|

Output Repeatability (–40°C to +85°C) |

± 0.05% FS |

|

Process Connections |

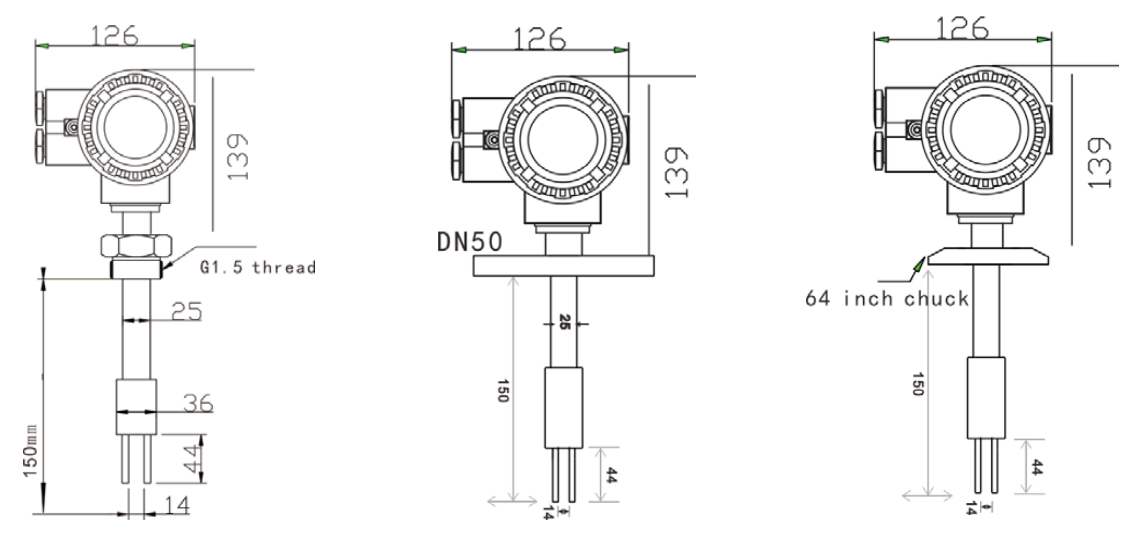

DIN 50 PN16 G1.5" thread, 3" tri-clamp, IDF, and RJT sanitary types |

|

|

IDF, and RJT sanitary types |

|

Ingress Protection |

IP65 |

|

Housing Material |

Aluminum alloy |

|

LF100C- |

A |

M |

L |

A |

1 |

D |

A |

A |

A |

M |

Details |

|

LF100C- |

|

|

|

|

|

|

|

|

|

|

LF100C Series Tuning Fork Resonant Density Meter (Concentration Meter) |

|

|

A |

|

|

|

|

|

|

|

|

|

Standard Type |

|

|

B |

|

|

|

|

|

|

|

|

|

Explosion-proof Type (Explosion protection level: Exd ia IIC T5 Ga; Protection grade: IP65) |

|

|

|

M |

|

|

|

|

|

|

|

|

M20X1.5 |

|

|

|

G |

|

|

|

|

|

|

|

|

G1/2 |

|

|

|

N |

|

|

|

|

|

|

|

|

NPT1/2 |

|

|

|

C |

|

|

|

|

|

|

|

|

Others (please specify) |

|

|

|

|

L |

|

|

|

|

|

|

|

Process Connection Type |

|

|

|

|

F |

|

|

|

|

|

|

|

Threaded ( 01 )DN50 (02)DN80 (03)DN100 (04) Others |

|

|

|

|

W |

|

|

|

|

|

|

|

Sanitary 1= 1.5"Clamp;2=2"Clamp; 3=3"Clamp;4=Others |

|

|

|

|

C |

|

|

|

|

|

|

|

Others: Please specify |

|

|

|

|

|

A |

|

|

|

|

|

|

01 = 128 mm (Standard) 02 = 150 mm |

|

|

|

|

|

B |

|

|

|

|

|

|

Rod Extension: 70 mm ~ 3000 mm (Optional) |

|

|

|

|

|

C |

|

|

|

|

|

|

Cable Extension: 1 ~ 8000 mm (Remote version optional) |

|

|

|

|

|

|

1 |

|

|

|

|

|

316 Stainless Steel |

|

|

|

|

|

|

2 |

|

|

|

|

|

Corrosion-resistant Coating: 316SS + PTFE |

|

|

|

|

|

|

3 |

|

|

|

|

|

Corrosion-resistant Coating: 316SS + PFA |

|

|

|

|

|

|

C |

|

|

|

|

|

1 = 2205 Duplex Stainless Steel 2 = Hastelloy 3 = Titanium 4 = Zirconium 5 = Others |

|

|

|

|

|

|

|

D |

|

|

|

|

24V DC± 10% |

|

|

|

|

|

|

|

|

A |

|

|

|

1-channel 4–20 mA 1 = Two-wire 2 = Four-wire |

|

|

|

|

|

|

|

|

B |

|

|

|

2-channel 4–20 mA (Four-wire only) |

|

|

|

|

|

|

|

|

C |

|

|

|

RS-485( modbus ) |

|

|

|

|

|

|

|

|

|

A |

|

|

Normal temperature: 0–100°C |

|

|

|

|

|

|

|

|

|

B |

|

|

High temperature: 0–150°C (Optional high-temperature heat sink) |

|

|

|

|

|

|

|

|

|

|

A |

|

Normal pressure: 0.2–0.3 MPa |

|

|

|

|

|

|

|

|

|

|

B |

|

Max pressure: ≤4 MPa |

|

|

|

|

|

|

|

|

|

|

|

M |

0—2.5g/cm³ |

|

|

|

|

|

|

|

|

|

|

|

Y |

0-100% |

|

|

|

|

|

|

|

|

|

|

|

Z |

( ) Other user requirements: Please specify |

|

Note: The selection table is for parameter selection only. Final configuration is based on parameters and corresponding codes for production. |

|||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Tuning Fork Resonance Density Meter (Concentration Meter) - LF100C Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Tuning Fork Resonance Density Meter (Concentration Meter) - LF100C Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Tuning Fork Resonance Density Meter (Concentration Meter) - LF100C Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .