If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsLFP Series RF Capacitance Level Transmitter

The RF capacitance level transmitter operates based on the principle that changes in material or liquid level cause a change in capacitance. The probe and the conductive tank wall form an equivalent capacitor. When the probe is in air, the capacitance (CA) is low. As material fills the tank and adheres to the probe, the capacitance increases. When the tank is full and the probe is completely covered, the capacitance reaches its maximum (CB). The measurable range is the difference in capacitance (ΔC = CB - CA), recommended for use within ΔC = 25 to 2000 pF.

Low power consumption, easy wiring (2-wire system)

Max. current consumption: 20mA

Excellent linearity (<±1% FS or ±0.5pF)

Temperature compensation, low temp. coefficient (±0.2% FS/°C or 0.1pF/°C)

Easy two-point calibration

No blind zones, suitable for all types of tanks

Resistant to high temperature, high pressure, and corrosive environments

On-site LED display

|

Model |

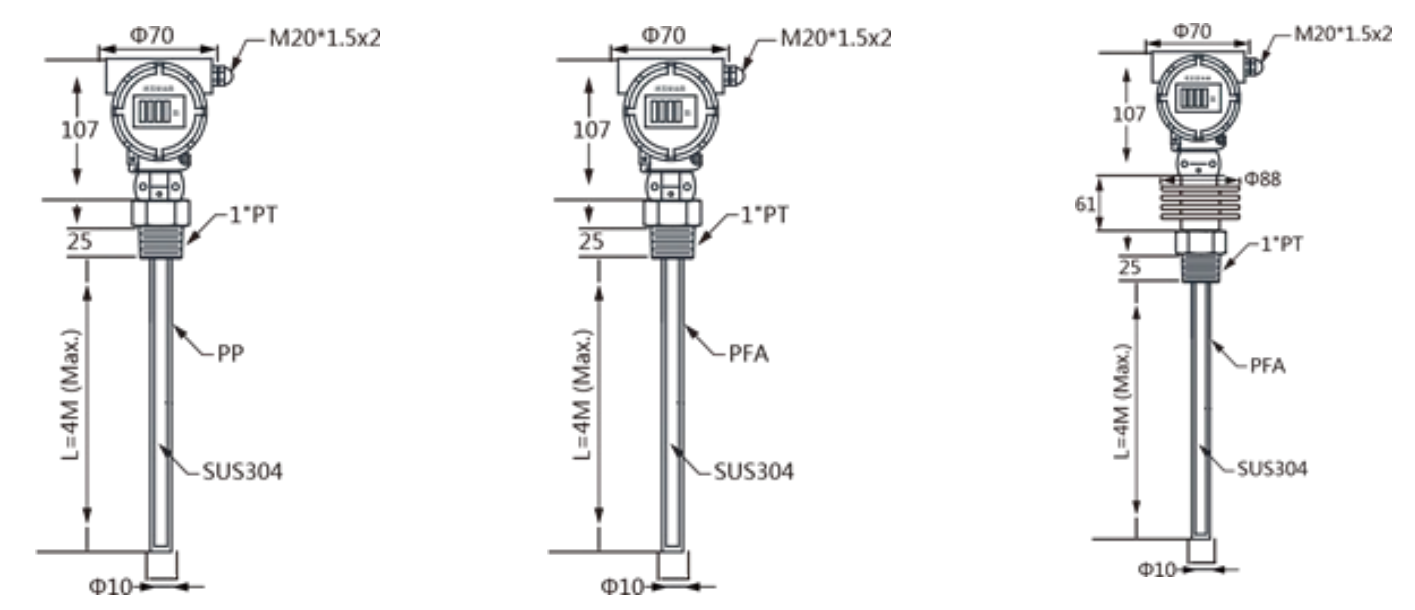

LFP10 (Rod, PP-coated) |

LFP20 (Rod, PP-coated) |

LFP21 (High-temp Rod, PFA-coated) |

|

Sensing Material |

SUS304 cable + PP coating |

SUS304 cable + PFA coating |

SUS304 + PFA coating |

|

Ambient Temp. |

-40~85°C |

-40~85°C |

-40~85°C |

|

LCD Display Temp. |

-20~85°C |

-20~85°C |

-20~85°C |

|

Operating Temp. |

-40~85°C |

-40~85°C |

-40~200°C |

|

Operating Voltage |

18~30VDC |

18~30VDC |

18~30VDC |

|

Analog Output |

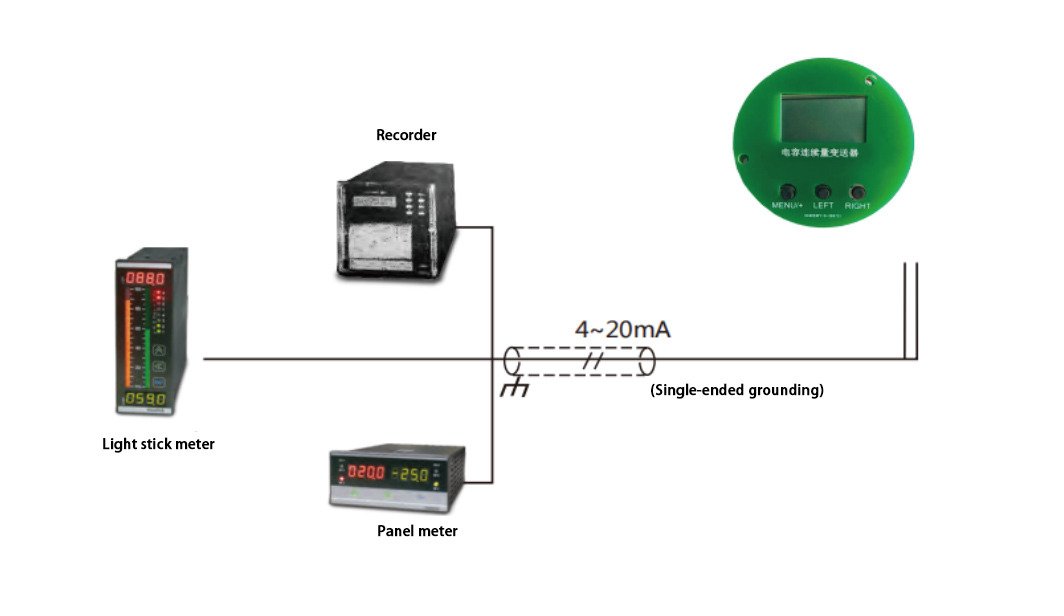

4~20mA (2-wire) |

4~20mA (2-wire) |

4~20mA (2-wire) |

|

Digital Output |

HART (optional) |

HART (optional) |

HART (optional) |

|

Detection Range |

20~2000pF |

20~2000pF |

20~2000pF |

|

Accuracy |

±1% FS or ±0.5pF |

±1% FS or ±0.5pF |

±1% FS or ±0.5pF |

|

Temp. Effect |

<±0.2% FS/°C or 0.1pF/°C |

<±0.2% FS/°C or 0.1pF/°C |

<±0.2% FS/°C or 0.1pF/°C |

|

Enclosure Protection |

IP65 |

IP65 |

IP65 |

|

Process Connection |

1"PT or 1"x5kg/cm² |

1"PT or 1"x5kg/cm² |

1"PT or 1"x5kg/cm² |

|

Weight |

Approx. 2.3kg (1m) |

Approx. 2.3kg (1m) |

Approx. 2.8kg (1m) |

|

Pressure |

32kg/cm² |

32kg/cm² |

32kg/cm² |

|

Note: High-temperature rod versions must use PFA coating (Model LFP21 series). |

|||

|

Model |

LFP30 (Cable, PP-coated) |

LFP31 (High-temp Cable, PFA-coated) |

LFP40 (Standard Rod Type) |

|

Sensing Material |

SUS304 cable + PP coating |

SUS304 cable + PFA coating |

SUS304 + PFA or PP |

|

Ambient Temp. |

-40~85°C |

-40~85°C |

-40~85°C |

|

LCD Display Temp. |

-20~85°C |

-20~85°C |

-20~85°C |

|

Operating Temp. |

-40~85°C |

-40~200°C |

-40~85°C (customizable to 200°C) |

|

Operating Voltage |

18~30VDC |

18~30VDC |

18~30VDC |

|

Analog Output |

4~20mA (2-wire) |

4~20mA (2-wire) |

4~20mA (2-wire) |

|

Digital Output |

HART (optional) |

HART (optional) |

HART (optional) |

|

Detection Range |

20~2000pF |

20~2000pF |

20~2000pF |

|

Accuracy |

±1% FS or ±0.5pF |

±1% FS or ±0.5pF |

±1% FS or ±0.5pF |

|

Temp. Effect |

<±0.2% FS/°C or 0.1pF/°C |

<±0.2% FS/°C or 0.1pF/°C |

<±0.2% FS/°C or 0.1pF/°C |

|

Enclosure Protection |

IP65 |

IP65 |

IP65 |

|

Process Connection |

1"PT or 1"x5kg/cm² |

1"PT or 1"x5kg/cm² |

1"PT or 1"x5kg/cm² |

|

Weight |

Approx. 2.3kg (1m) |

Approx. 2.3kg (1m) |

Approx. 2.8kg (1m) |

|

Pressure |

32kg/cm² |

32kg/cm² |

32kg/cm² |

|

Note: High-temperature cable models must use PFA coating (Model LFP31 series). |

|||

|

LFP- |

N |

1 |

TD |

4 |

Q |

1 |

L0 |

T |

P |

Detailed |

|

LFP- |

|

|

|

|

|

|

|

|

|

Right Column (LFP Series RF Capacitance Level Transmitter) |

|

Certification

|

N |

|

|

|

|

|

|

|

|

Non-Ex-proof |

|

I |

|

|

|

|

|

|

|

|

Intrinsically Safe: Ex ia IICT4/T6 Ga/Gb |

|

|

D |

|

|

|

|

|

|

|

|

Explosion-Proof: Ex d IICT4/T6 Ga/Gb |

|

|

输出方式

|

|

1 |

|

|

|

|

|

|

|

24VDC, Output: 4-20mA (2-wire) |

|

|

2 |

|

|

|

|

|

|

|

24VDC, Output: 4-20mA + HART (2-wire) |

|

|

Process Connection

|

|

|

TD |

|

|

|

|

|

|

3/4" PT Thread |

|

|

|

TE |

|

|

|

|

|

|

G1 Thread |

|

|

|

|

TG |

|

|

|

|

|

|

1" PT Thread (Standard) |

|

|

|

|

FA |

|

|

|

|

|

|

DN25 PN1.6 RF Flange |

|

|

|

|

FD |

|

|

|

|

|

|

DN50 PN1.6 RF Flange |

|

|

|

|

SS |

|

|

|

|

|

|

Special thread (≥3/4") or flange (≥DN25) available |

|

|

Wetted Material

|

|

|

|

4 |

|

|

|

|

|

SUS304 + PFA |

|

|

|

|

6 |

|

|

|

|

|

SUS304 + PTFE (Sintered) |

|

|

|

|

|

7 |

|

|

|

|

|

SUS304 + Ceramic (200–600°C) |

|

|

|

|

|

8 |

|

|

|

|

|

SUS316 + Ceramic (200–600°C) |

|

|

|

|

|

9 |

|

|

|

|

|

SUS310S + Ceramic (200–1100°C) |

|

|

Housing Material |

|

|

|

|

A |

|

|

|

|

Aluminum alloy with coating |

|

Electrical Interface

|

|

|

|

|

|

1 |

|

|

|

M20* 1.5 |

|

|

|

|

|

|

2 |

|

|

|

1/2NPT |

|

|

|

|

|

|

|

3 |

|

|

|

Special available |

|

|

Insertion Length

|

|

|

|

|

|

|

L0 |

|

|

Rod Type: Standard (300–500mm) |

|

|

|

|

|

|

|

LA |

|

|

Extended (500–3000mm) |

|

|

|

|

|

|

|

|

LB |

|

|

Cable Type: Extended (3000–10000mm) |

|

|

|

|

|

|

|

|

LC |

|

|

Compact Rod (150–300mm) |

|

|

|

|

|

|

|

|

LD |

|

|

Flat Plate Type |

|

|

|

|

|

|

|

|

L... |

|

|

Custom |

|

|

Temperature Range

|

|

|

|

|

|

|

|

T |

|

Temperature:-40-80℃ |

|

|

|

|

|

|

|

|

T... |

|

Other max values available (Max 260°C) |

|

|

Pressure Range

|

|

|

|

|

|

|

|

|

P |

Normal pressure |

|

|

|

|

|

|

|

|

|

P... |

Custom pressure values (bar) |

|

|

Note: This selection table is for technical reference only. Final factory model codes will reflect selected options. |

||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. LFP Series RF Capacitance Level Transmitter Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As LFP Series RF Capacitance Level Transmitter Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer LFP Series RF Capacitance Level Transmitter Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .