If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsMagnetic Level Indicator - LF800

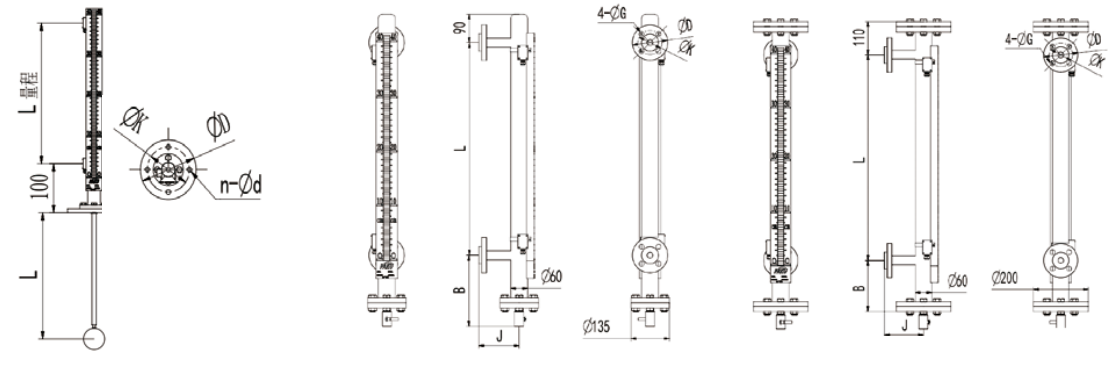

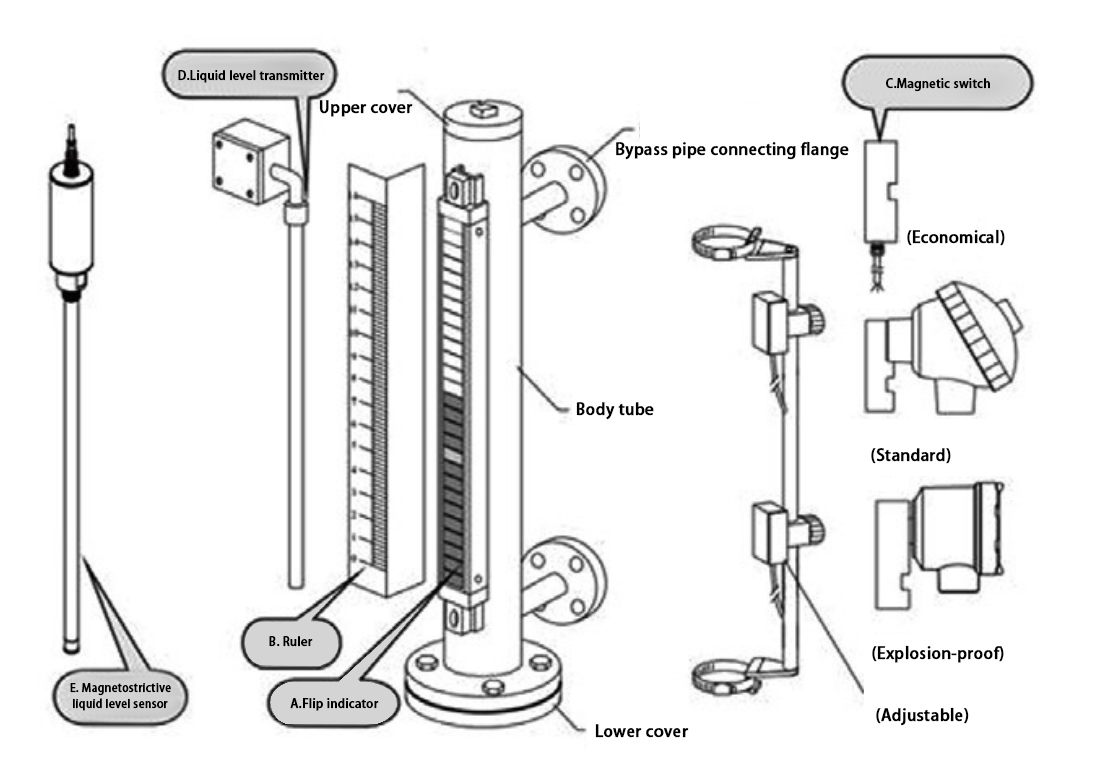

The LF800 series magnetic level indicator consists of a main body, a flap display panel (composed of red and white magnetic flaps), a float, flange covers, etc. It is used for liquid level measurement in various types of containers. It is suitable for applications such as high temperature, explosion-proof, corrosion-resistant environments, and food & beverage industries, serving both local and remote level indication and control.

The LF800 can achieve high sealing, leak-proof performance, and reliable level measurement under high temperature, high pressure, high viscosity, and highly corrosive conditions. It offers full-range measurement with no dead zones, clear display, and intuitive readings. With an optional level alarm and control switch, it can provide upper and lower limit alarms and controls. Equipped with a level transmitter, it converts the level/interface signal into a 2-wire 4–20 mA DC standard signal, enabling remote monitoring, indication, recording, and control.

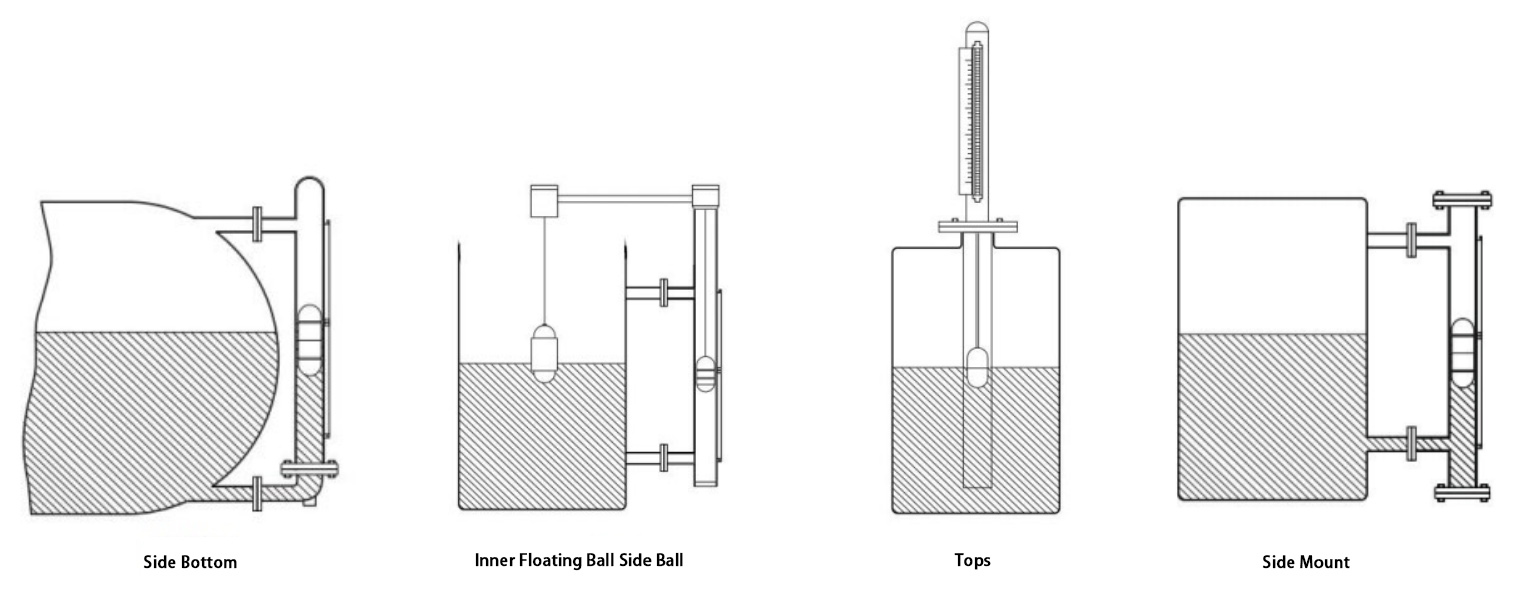

LF800 series indicators adopt either top-mounted or side-mounted bypass tube installation. The main body is equipped with a magnetic flap display, level switch, and level transmitter. The magnetic unit is either placed inside the float or linked with the float via a rod. As the float moves with the liquid level, it flips the magnetic display flaps. The level switch activates at corresponding level points, while the level sensor outputs a resistance signal influenced by the float’s magnetic field. This resistance signal is then converted by a transmitter into a 4–20 mA current signal output.

Measuring Range: 150–8000 mm

Working Pressure: Atmospheric; 1.6 MPa; 4.0 MPa; 6.4 MPa; 10 MPa

Connection Type: Flange or Threaded

Body Material: 304 Stainless Steel

Flap Material: Aluminum Alloy

Medium Density: 0.8–1.0 g/cm³

Medium Viscosity: ≤ 0.4 Pa·s

Operating Temperature: -20 to 80°C

Medium Temperature: -20 to 100°C

Suitable for level measurement of a wide range of liquids; various installation options

The measuring medium is fully isolated from the display mechanism; excellent sealing and leak prevention

Capable of high-pressure, high-temperature measurement with high reliability

Integrated local display, remote transmission, and alarm control switch, fully adjustable

Bi-color luminous display strip for clear, continuous, and direct indication over a large range; adjustable viewing direction

Strong anti-vibration performance for fluctuating level environments

Simple structure, easy installation, and low maintenance costs

|

PN53E- |

Z |

A |

G4 |

D |

A |

Q |

Z |

1 |

Selection Guide |

|

PN53E- |

|

|

|

|

|

|

|

|

PN53E Series Electronic Digital Pressure Switch Transmitter |

|

|

Z |

|

|

|

|

|

|

|

Positive pressure |

|

|

F |

|

|

|

|

|

|

|

Negative pressure |

|

|

|

A |

|

|

|

|

|

|

Pressure Ranges :-1.. 1bar or 0.. 1bar |

|

|

|

B |

|

|

|

|

|

|

Pressure Ranges :-1..2bar or 0..2bar |

|

|

|

C |

|

|

|

|

|

|

Pressure Ranges :-1..5bar or 0..5bar |

|

|

|

D |

|

|

|

|

|

|

Pressure Ranges :0.. 10bar |

|

|

|

E |

|

|

|

|

|

|

Pressure Ranges :0..25bar |

|

|

|

F |

|

|

|

|

|

|

Pressure Ranges :0.. 100bar |

|

|

|

G |

|

|

|

|

|

|

Pressure Ranges :0.. 160bar |

|

|

|

H |

|

|

|

|

|

|

Pressure Ranges :0..250bar |

|

|

|

I |

|

|

|

|

|

|

Pressure Ranges :0..400bar |

|

|

|

J |

|

|

|

|

|

|

Pressure Ranges :0..600bar |

|

|

|

K |

|

|

|

|

|

|

Custom range (e.g., 300 bar) |

|

|

|

|

G4 |

|

|

|

|

|

G1/4 thread |

|

|

|

|

G2 |

|

|

|

|

|

G1/2 thread |

|

|

|

|

K5 |

|

|

|

|

|

Clamp connection (Ø50.5 mm, max 16 bar) |

|

|

|

|

P |

|

|

|

|

|

Flush diaphragm connection |

|

|

|

|

|

D |

|

|

|

|

Custom thread |

|

|

|

|

|

H |

|

|

|

|

External thread |

|

|

|

|

|

K |

|

|

|

|

Internal thread |

|

|

|

|

|

|

A |

|

|

|

2 relay outputs |

|

|

|

|

|

|

B |

|

|

|

2 relay outputs + 4–20mA analog output |

|

|

|

|

|

|

|

Q |

|

|

Direct cable output |

|

|

|

|

|

|

|

|

Z |

|

Damping screw (optional) |

|

|

|

|

|

|

|

|

S |

|

Heat sink (optional) |

|

|

|

|

|

|

|

|

|

1 |

Axial |

|

|

|

|

|

|

|

|

|

2 |

Radial |

|

|

|

|

|

|

|

|

|

3 |

Axial flange type |

|

For 316L stainless steel housing, please specify when ordering. |

|||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Magnetic Level Indicator - LF800 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Magnetic Level Indicator - LF800 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Magnetic Level Indicator - LF800 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .