If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsAnti-corrosion ultra-high precision displacement (float level) sensor-LF701

High reliability: Since the magnetostrictive level gauge adopts the magnetostrictive principle, it has no mechanical moving parts, therefore no friction and no wear. The entire transducer is sealed inside the tube and does not contact the measured medium. The sensor works reliably and has a long service life.

High accuracy: Since the magnetostrictive level gauge works with waveguide pulses, during operation the displacement is determined by measuring the time between the start pulse and the end pulse. Therefore, the measurement accuracy is high, with a resolution better than 0.01% F.S., which is difficult to achieve with other sensors.

Easy installation and simple maintenance: Magnetostrictive level gauges are generally installed through existing nozzles on the top of the tank, which is particularly suitable for underground tanks and in-service tank installations, and the installation process does not affect normal production.

Facilitates system automation: Magnetostrictive level gauges adopt standard output signals, which are convenient for microcomputer signal processing, easy to achieve networked operation, and improve the automation level of the entire measurement system.

With the rapid development of science and technology, high-tech products have been widely used in various industries. Magnetostrictive level gauge sensors, with high technological content, are used for liquid level measurement in various storage tanks. This type of level instrument has the characteristics of high accuracy, strong environmental adaptability, and easy installation. Therefore, it is widely used in the fields of liquid level measurement in petroleum, chemical industry, etc., and is gradually replacing other traditional sensors, becoming a premium product in level measurement.

Measurement objects: 1~2 positions

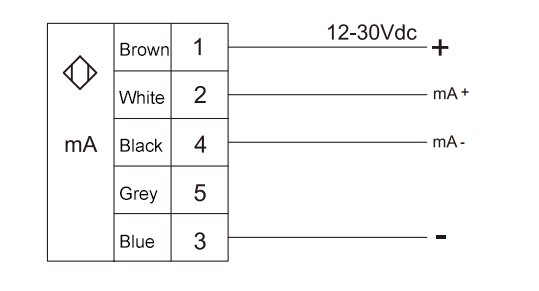

Power supply: +24VDC+10%, +15VDC+10%

Output mode (optional reverse output): 05VDC, 010VDC, 4~20mA

5~+5VDC, -10~+10VDC Modbus RS485, Hart

Effective measurement range: G.F structure: 505000mm, R structure: 400020000mm

Load characteristics: Current output: maximum load resistance 600Ω

Voltage output: maximum load current 2mA

Working current: <70mA

Working temperature: 4085°C, -40120°C, -40~200°C

Storage temperature: -40~100°C

Nonlinearity error: <+0.05% F.S., for ranges below 300mm, maximum error 150μm

Repeatability error: <+0.002% F.S.

Resolution: 16-bit D/A conversion

Hysteresis: <0.002% F.S.

Temperature influence: <0.007% F.S./°C

Zero adjustment range: 100% F.S.

Update time / Sampling frequency: Related to the range, not exceeding 20ms

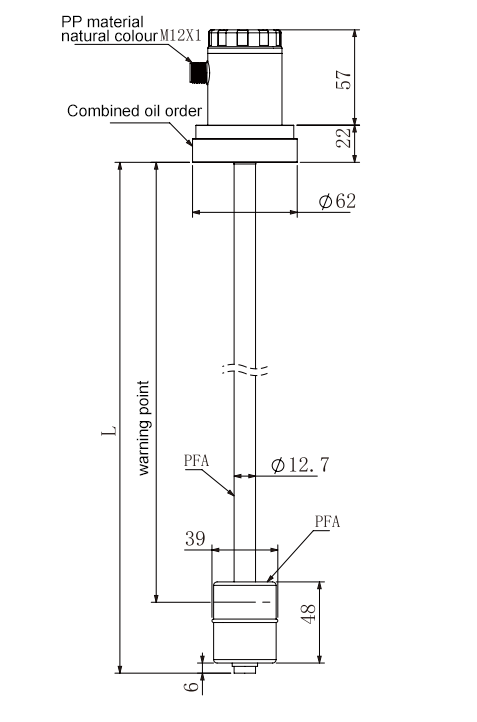

Measuring rod structure: Corrosion-resistant rod structure

Measuring rod material: PFA/PVDF

Installation interface: O-ring connection

Cable outlet: Aviation plug

Explosion-proof mark: ExdIIBT5 (explosion-proof type)

Protection grade: IP65 (can be made to IP67 or IP68 as per customer requirement)

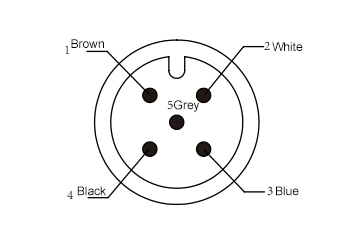

| Needle | Cable | Signal |

| 1 | Brown | 24v+ |

| 2 | White | mA+ |

| 3 | Blue | 24V- |

| 4 | Black | mA- |

| 5 | Grey |

| LF701- | A | L | F | 1 | A | Details | ||||||||||||||

| LF701- | LF701 Series Corrosion-Resistant Ultra-High Precision Displacement (Float Level) Sensor | |||||||||||||||||||

| A | Float level type | |||||||||||||||||||

| L | Effective stroke (mm): 50-20000 (Flexible rod is recommended for over 5 meters) |

|||||||||||||||||||

| F | Material: PVDF | |||||||||||||||||||

| A | Material: PFA | |||||||||||||||||||

| 1 | Output Signal: 4-20mA current | |||||||||||||||||||

| 2 | Output Signal: 0-20mA current | |||||||||||||||||||

| 3 | Output Signal: 0-5V Voltage | |||||||||||||||||||

| 4 | Output Signal: 0-10V Voltage | |||||||||||||||||||

| 5 | Output Signal: RS485 | |||||||||||||||||||

| 6 | Output Signal: Canbus | |||||||||||||||||||

| 7 | Output Signal: Mudbus | |||||||||||||||||||

| 8 | Output Signal: SSI | |||||||||||||||||||

| A | Waterproof cable connector | |||||||||||||||||||

| B | Waterproof Aviation Plugs | |||||||||||||||||||

| C | Hussmann Plugs | |||||||||||||||||||

| * The selection table is only for parameter selection; factory models correspond to parameter codes. | ||||||||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Anti-corrosion ultra-high precision displacement (float level) sensor-LF701 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Anti-corrosion ultra-high precision displacement (float level) sensor-LF701 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Anti-corrosion ultra-high precision displacement (float level) sensor-LF701 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .