If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsFlow, temperature, pressure integrated switch sensor-SN560

First, PN500 series compact diffusion silicon type pressure transmitter, wide choice, compact structure, suitable for more severe environment, high can principle characteristics SN560-flow temperature pressure dependability. Wide range (0..1000bar), can be used to measure gauge pressure, absolute pressure. Suitable for mechanical equipment, hydraulic and pneumatic devices, locomotives, pressure control.

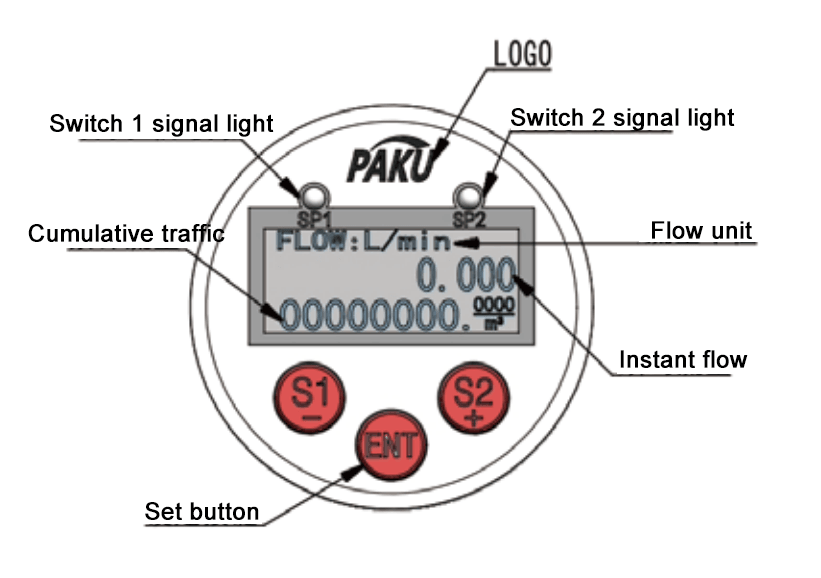

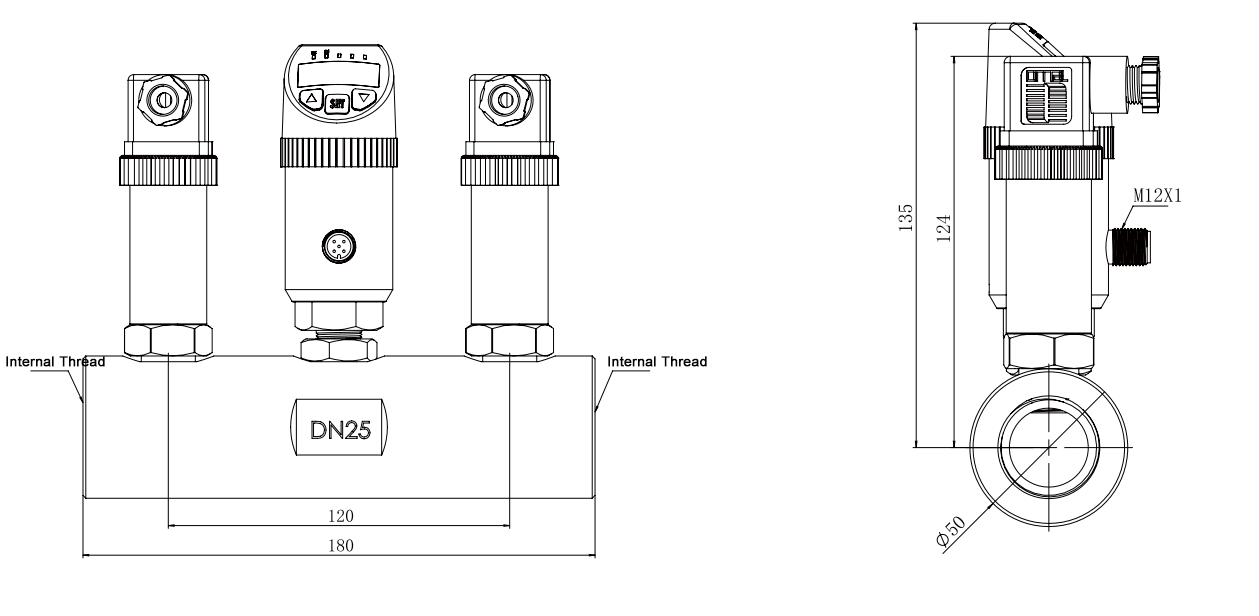

Second, SN5C series electronic turbine flow sensor and an intelligent flow switch, is a compact flow sensor, with a small size, easy to set the advantages of the built-in intelligent circuit, can be set arbitrarily flow upper and lower limits of the alarm value can be remotely monitored the real-time flow conditions, the full range of parameters on-site any setup, the turbine measurement medium through the flow through the sensor intelligent circuit processing any programming.

-Applicable to the measurement medium, such as water, diesel, petrol, hydraulic oil.

-Increase in the traditional turbine flowmeter on the basis of the upper and lower limits of the role of the alarm.

Third, T450 series temperature sensor contains a PT100 probe, PT100 resistance will change with the temperature change, T450 internal circuit will be converted into linear analogue output. Simple installation, a variety of ranges can be selected, a variety of specifications of the probe can be selected, all stainless steel shell, compact and rugged structure. And optional field instruments and cabinet-mounted control table.

Fourth, for the measurement of fluid pressure, flow, temperature of this P.Q.T joints are widely used: starters, locomotives, hydraulic devices.

Customised high-pressure models are available, with a pressure resistance of 400 bar.

| Called the diameter DN( mm ) |

Flow range( m³/H ) | Nominal pressure PN( MPa ) |

Maximum pressure loss ( MPa ) |

|||||||||||||||||||||

| Lower limit | Upper limit | Lower limit | Upper limit | Lower limit | Upper limit | |||||||||||||||||||

| 2 | 0.03 | 0.16 | Thread pressure resistance: 6.3 Flange pressure resistance: 1.6 Please indicate the special pressure resistance |

0.15 | ||||||||||||||||||||

| 4 | 0.04 | 0.25 | 0.12 | |||||||||||||||||||||

| 6 | 0.1 | 0.6 | 0.08 | |||||||||||||||||||||

| 10 | 0.2 | 1.2 | 0.05 | |||||||||||||||||||||

| 15 | 0.6 | 4 | 0.6 | 6 | 0.035 | |||||||||||||||||||

| 20 | 0.8 | 8 | ||||||||||||||||||||||

| 25 | 1.6 | 10 | 1 | 10 | ||||||||||||||||||||

| 32 | 1.5 | 15 | ||||||||||||||||||||||

| 40 | 3 | 20 | 3 | 20 | 2 | 20 | 0.025 | |||||||||||||||||

| 50 | 6 | 40 | 6 | 40 | 4 | 40 | ||||||||||||||||||

| 65 | 8 | 80 | ||||||||||||||||||||||

| 80 | 16 | 100 | 16 | 100 | 10 | 100 | ||||||||||||||||||

| 100 | 25 | 160 | 25 | 160 | 20 | 222 | ||||||||||||||||||

| 125 | 25 | 250 | ||||||||||||||||||||||

| 150 | 60 | 400 | 50 | 300 | 40 | 400 | ||||||||||||||||||

| 200 | 100 | 600 | 80 | 800 | ||||||||||||||||||||

| 250 | 160 | 1000 | 120 | 1200 | ||||||||||||||||||||

| 300 | 260 | 1600 | 180 | 1800 | ||||||||||||||||||||

| PN500- | GB... | C | G4 | H | 4 | C | B | Detailed description | ||||||||||||||||

| PN500- | PN500 Series General Purpose Pressure Transmitter | |||||||||||||||||||||||

| GB.. . | Gauge pressure range: bar (unit), refer to the range table | |||||||||||||||||||||||

| AB .. . | Absolute pressure range: bar (unit), refer to the range table | |||||||||||||||||||||||

| GP.. . | Optional range: KPa (unit), user-defined | |||||||||||||||||||||||

| Customised ranges | ||||||||||||||||||||||||

| B | Accuracy class : 0.25 | |||||||||||||||||||||||

| C | Accuracy class: 0.5 | |||||||||||||||||||||||

| N4 | Interface thread: NPT1/4 | |||||||||||||||||||||||

| N2 | Interface thread: NPT1/2 | |||||||||||||||||||||||

| G4 | Interface thread : G1/4 | |||||||||||||||||||||||

| G2 | Interface thread : G1/2 | |||||||||||||||||||||||

| M2 | Interface thread : M20* 1.5 | |||||||||||||||||||||||

| Customised interface threads | ||||||||||||||||||||||||

| H | H: male thread K: female thread | |||||||||||||||||||||||

| 4 | 4-20mA output | |||||||||||||||||||||||

| 1 | 1-5V output | |||||||||||||||||||||||

| 0 | 0-10V output | |||||||||||||||||||||||

| C | M12* 1 connector | |||||||||||||||||||||||

| B | No damper, no heat sink | |||||||||||||||||||||||

| SN5C - | 025 | D | P | 2 | K | 1 | Q | Detailed Description | ||||||||||||||||

| SN5C - | SN5C Series Electronic Turbine Flow Sensor | |||||||||||||||||||||||

| 025 | Sizing option ,025 for DN25 pipe (Pipe can be selected according to the dimension drawing, please consult sales engineer for special pipe sizes) | |||||||||||||||||||||||

| D | Power supply: 24V | |||||||||||||||||||||||

| P | PNP output | |||||||||||||||||||||||

| N | NPN output | |||||||||||||||||||||||

| 1 | Two-way switching | |||||||||||||||||||||||

| 2 | Two switching + analogue 4-20mA outputs | |||||||||||||||||||||||

| 3 | 2-way switching + pulse output | |||||||||||||||||||||||

| K | Female thread mounting | |||||||||||||||||||||||

| H | External thread mounting | |||||||||||||||||||||||

| D | Flange connection | |||||||||||||||||||||||

| G | Sanitary clamp connection | |||||||||||||||||||||||

| 1 | Pressure: 16bar | |||||||||||||||||||||||

| 2 | Pressure: 25bar | |||||||||||||||||||||||

| 3 | Pressure: 63 bar | |||||||||||||||||||||||

| 4 | Pressure resistance: 250 bar (diameter ≤ DN50) | |||||||||||||||||||||||

| 5 | Pressure resistance: 400 bar (diameter ≤ DN50) | |||||||||||||||||||||||

| Q | M 12*1 connector | |||||||||||||||||||||||

| T450- | A | M | A | 4 | D1 | G4 | B | Detailed Description | ||||||||||||||||

| T450- | T450 Series Integrated Temperature Transmitter | |||||||||||||||||||||||

| A | Probe Length L 25 mm (without threads) | |||||||||||||||||||||||

| B | Probe Length L 50 mm (without threads) | |||||||||||||||||||||||

| C | Probe Length L 75 mm (without threads) | |||||||||||||||||||||||

| D | Probe length L = 100 mm (without thread) | |||||||||||||||||||||||

| ... | Customised probe length L = mm (without thread) | |||||||||||||||||||||||

| H | External threaded connection | |||||||||||||||||||||||

| A | Measuring range -50 ...0 °C | |||||||||||||||||||||||

| B | Measuring range -50 ...50°C | |||||||||||||||||||||||

| C | Measuring range 0...50 ℃ | |||||||||||||||||||||||

| D | Measuring range 0... 100℃ | |||||||||||||||||||||||

| E | Measuring range 0... 120℃ | |||||||||||||||||||||||

| F | Measuring range 0... 150℃ | |||||||||||||||||||||||

| G | Measuring range 0...200℃ | |||||||||||||||||||||||

| ... | Customised ranges, e.g. -20... 100°C Option: H-20...10 0 |

|||||||||||||||||||||||

| 4 | Analogue range output :4...20mA | |||||||||||||||||||||||

| 41 | Armoured analogue range output : 4...20mA | |||||||||||||||||||||||

| 0 | Analogue range output:0. ..10V | |||||||||||||||||||||||

| 1 | Analogue range outputs: 1. ..5 V | |||||||||||||||||||||||

| D1 | Probe diameter Ф6 | |||||||||||||||||||||||

| D2 | Probe diameter Ф8 | |||||||||||||||||||||||

| D12 | Customised probes, e.g. Ø φ12 | |||||||||||||||||||||||

| G4 | Threaded connector G1/ 4 | |||||||||||||||||||||||

| G2 | Threaded connector G1/ 2 | |||||||||||||||||||||||

| M2 | Threaded connector M20* 1.5 | |||||||||||||||||||||||

| Customised thread | ||||||||||||||||||||||||

| A | Plug-in M12* 1 (2 metre cable as standard) | |||||||||||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Flow, temperature, pressure integrated switch sensor-SN560 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Flow, temperature, pressure integrated switch sensor-SN560 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Flow, temperature, pressure integrated switch sensor-SN560 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .