If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get coupons(Sanitary) PT100 temperature sensor-T310

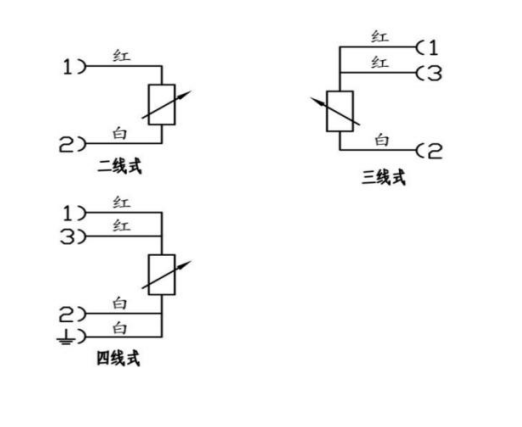

The T310 includes a PT100 probe. PT100 resistance varies with temperature. The T310 is available in two wire, three wire and four wire types.

Simple installation, a variety of range optional, a variety of specifications probe optional, stainless steel housing, compact and firm structure. And can be equipped with field instrument and cabinet type control table.

- Measuring range: -50℃ ... 200℃ (user-defined)

- Linear degree: < 0.1%

- Accuracy: ±0.2K +0.2% full scale

- Resolution: 0.1K

- Pressure: Φ6 type: probe 400bar, Φ8 type: probe 100bar

- Temperature effect: 0.1K/10K

- Response time: 2.3 seconds

- Working voltage: 12... 30Vdc

- Electrical protection: anti-pole, overload protection

- Sensor: PT100

- Ambient temperature: -25... 80 ℃

- Protection grade: IP65

- Shell material: 304 stainless steel

- Contact part material: 304 stainless steel

- Electrical connection: Hersman

| T310- | specification | |||||

| T310- | T310 series (sanitary type) PT100 temperature sensor |

|||||

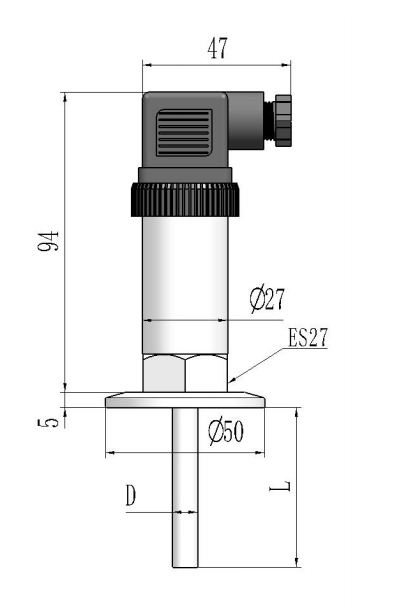

| A | Probe length L 25mm (without thread) | |||||

| B | Probe length L 50mm (without thread) | |||||

| C | Probe length L is 75mm (without thread) | |||||

| D | Probe length L is 100mm (without thread) | |||||

| L... | Custom probe length L= mm (without thread) | |||||

| D1 | The probe diameter is Ф6 | |||||

| D2 | The probe diameter is Ф8 | |||||

| D12 | Custom probe, for example diameter Φ 12 | |||||

| F | flange | |||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | ||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. (Sanitary) PT100 temperature sensor-T310 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As (Sanitary) PT100 temperature sensor-T310 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer (Sanitary) PT100 temperature sensor-T310 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .