If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsDigital display anti-corrosion ceramic piezoresistive pressure sensor-PN80E

The PN80E series electronic pressure sensor adopts a ceramic piezoresistive chip, high-density polymer material resistant to strong acids and alkalis, and a corrosion-resistant cable. Equipped with an on-site LED digital display to show the current pressure or setting menu.

Maximum measuring range: -1...600bar. Digital LED displays pressure value and switch status. Menu allows setting of switch points, start/end of analog output, output functions, memory functions, and display functions. Settings can be completed without being on site. High reliability, output can be directly connected to a PLC. M12 locking connector for easy assembly/disassembly and high protection rating.

Can measure positive or negative pressure. With both switching and analog output, the sensor can be used as a pressure switch or as a pressure transmitter.

The anti-corrosion type pressure transmitter is mainly used for industries involving strong acids, strong alkalis, and other highly corrosive media, such as in water disinfection, chemical engineering, battery equipment, and also in food hygiene and medical pressure measurement and control.

Supply voltage: 12...30Vdc

Measuring range: Customized according to user requirements

Overload limit: 1.5 times of full scale

Measured medium: Corrosive liquids, fluids, gases

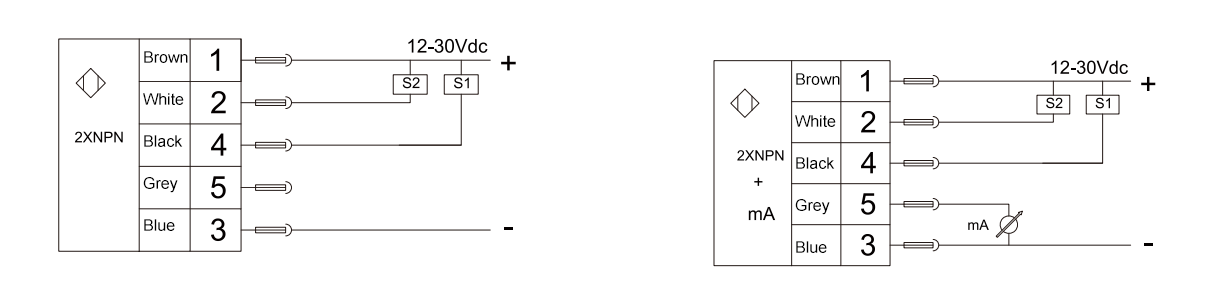

Display housing material: PVC

Body material: PTFE

Pressure type: Gauge pressure

Measuring range: 0~50KPa~100KPa~600KPa~5000KPa

Comprehensive accuracy: 0.2%FS, 0.5%FS, 1.0%FS

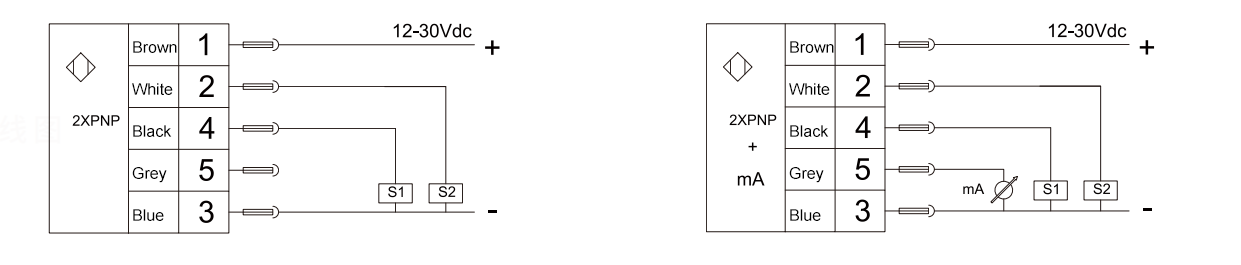

Output type: PNP, NPN; Normally open/closed selectable

S1, S2 output current: <500mA; Response time <10ms

Switching accuracy: ≤±0.5% F.S.

Analog current output accuracy: ≤±0.5% F.S.

Output signal: 4~20mA (2-wire), 1~5V, 0~10V (3-wire)

Supply voltage: 24DCV (15~36DCV), special voltage range available upon request

Medium temperature: -20~85℃; Ambient temperature: Room temp (-20~85℃)

Zero drift due to temperature: ≤±0.05%FS/℃

Span drift due to temperature: ≤±0.05%FS/℃

Compensation temperature: 0~70℃

Safe overload: 150%FS; Ultimate overload: 200%FS

Response time: 5ms (up to 90%FS)

Load resistance: Current output type: 800Ω; Voltage output type: >5KΩ

Gland cable outlet

| PN80E- | P | Z | A | G4 | H | D | A | Detailed | |||||

| PN80E- | PN80E Digital Anti-corrosion Ceramic Piezoresistive Pressure Sensor | ||||||||||||

| P | PNP output | ||||||||||||

| N | NPN output | ||||||||||||

| Z | Positive pressure | ||||||||||||

| F | Negative pressure | ||||||||||||

| A | Setting range: -1... 1bar or 0...1 | ||||||||||||

| B | Setting range: -1...2bar or 0...2bar | ||||||||||||

| C | Setting range: -1...5bar or 0...5bar | ||||||||||||

| D | Setting range: 0...10bar | ||||||||||||

| E | Setting range: 0...25bar | ||||||||||||

| F | Setting range: 0...100bar | ||||||||||||

| G | Setting range: 0...160bar 160bar | ||||||||||||

| H | Setting range: 0...250bar | ||||||||||||

| I | Setting range: 0...400bar | ||||||||||||

| J | Setting range: 0..600bar | ||||||||||||

| K | Custom range, e.g. 300bar | ||||||||||||

| G4 | Thread connection: G1/4 | ||||||||||||

| G2 | Thread connection: G1/2 | ||||||||||||

| P3 | Thread connection: PT3/8 | ||||||||||||

| P | Flush diaphragm connection | ||||||||||||

| Custom threads | |||||||||||||

| H | External thread | ||||||||||||

| K | Internal thread | ||||||||||||

| A | 1 switch output | ||||||||||||

| B | 2 switch outputs | ||||||||||||

| C | 1 analog 4-20mA output | ||||||||||||

| D | 1 switch + 1 analog 4-20mA output | ||||||||||||

| E | 2 switch + 1 analog 4-20mA output | ||||||||||||

| F | 2 switch + 1 analog 1-5V output | ||||||||||||

| A | Gland cable outlet | ||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Digital display anti-corrosion ceramic piezoresistive pressure sensor-PN80E Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Digital display anti-corrosion ceramic piezoresistive pressure sensor-PN80E Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Digital display anti-corrosion ceramic piezoresistive pressure sensor-PN80E Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .