If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Product 3D Image Get couponsCompact differential pressure transmitter-PN51

PN51 series diffused silicon differential pressure transmitter is composed of double isolation differential pressure sensor and integrated amplifier circuit, which has the advantages of high stability and good dynamic measurement performance. It is equipped with high-performance microprocessor to correct and compensate sensor nonlinearity and temperature drift, realize accurate digital data transmission, field equipment diagnosis, remote two-way communication and other functions, suitable for use in the measurement and control of liquid and gas. This transmitter has a variety of range, can meet the needs of all kinds of users. It is widely used in metallurgy, machinery, petroleum, chemical industry, power station, light industry, food, environmental protection, national defense and scientific research in various fields.

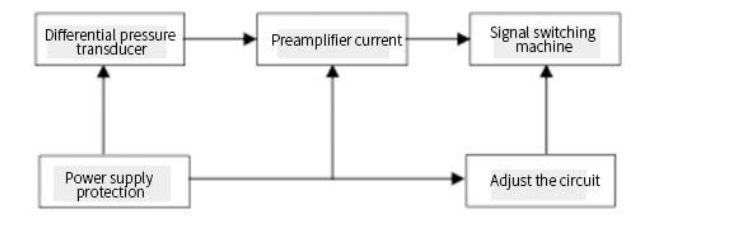

The working principle of diffused silicon differential pressure transmitter is: the process pressure acts on the sensor, the sensor is the output voltage signal proportional to the pressure, the voltage signal is transformed into 4-20mA standard signal through the amplifier circuit. The power supply protection circuit provides excitation for the sensor, and the sensor adopts precision temperature compensation circuit. Its working principle block diagram is as follows:

| range ability | 0... 0.2 bar to zero... 35bar | ||||||

|

accuracy |

±0.5% | ||||||

| power supply | 24VDC(10-30)VDC | ||||||

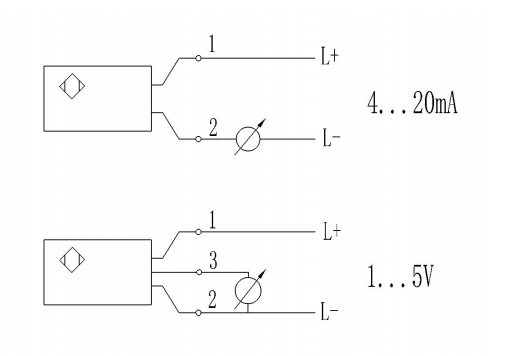

| signal output | 4-20mA DC | ||||||

| long-term stability | Plus or minus 0.2% or less F.S/year | ||||||

| over load pressure | ≤ 3 times of rated pressure | ||||||

| operating temperature range |

( -20~80 )℃ | ||||||

| size of interface | customizable | ||||||

| PN51- | ... | A | G4 | H | 1 | specification | |||||

| PN51- | PN51 series exquisit | ||||||||||

| ... | Range: 0... 0.2 bar to zero... 35bar (user customizable) |

||||||||||

| A | Output: 4-20 ma | ||||||||||

| B | Output: 0 to 5v | ||||||||||

| C | Output: 1-5 v | ||||||||||

| D | Output: 0 to 10v | ||||||||||

| G4 | Interface thread: G1/4 | ||||||||||

| G2 | Interface thread: G1/2 | ||||||||||

| N4 | Interface thread: NPT1/4 | ||||||||||

| H | RA | ||||||||||

| K | RI | ||||||||||

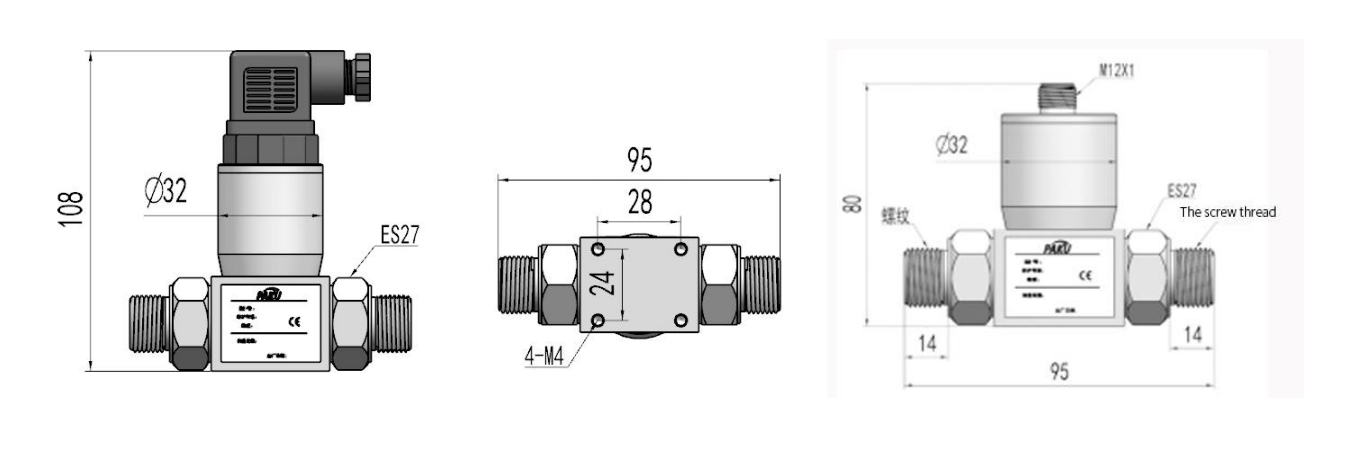

| 1 | Hersman joint | ||||||||||

| 2 | M12 x 1 connector | ||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | |||||||||||

- Differential pressure transmitter is small in size and light in weight. It can be installed directly on the measuring point during installation. Pay attention to check the sealing of the pressure interface to prevent the impact of air leakage on the measurement accuracy.

- According to the provisions of the wire connection, the transmitter can enter the working state. When the measurement accuracy is high, the instrument should be energized for half an hour before entering the working state.

- The differential pressure transmitter is recommended to be installed with a two-way valve to prevent excessive static pressure at both ends of the transmitter.

- Differential pressure transmitters shall be used in gases and liquids that are not corrosive to 316L stainless steel diaphragms.

- Wiring should be in strict accordance with the instructions to ensure the normal operation of the transmitter.

- The shielded cable can be used when the field interference is larger or the requirements are higher.

Technology Co., Ltd.

en

en English

English Русский

Русский España

España عرب .

عرب .