If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsExplosion-proof general purpose pressure transmitter-PN30D

PN30D series adopts high performance voltage sensing chip, with advanced circuit processing and temperature compensation technology, to convert pressure changes into linear current or voltage signals. The product has HATR communication, RS485 communication and self-interrupting function, the user uses the handheld terminal or the field bus system to transmit, read, display and input all the working information and additional information of the transmitter for a long distance. It can be used to delete gauge pressure, negative pressure and absolute pressure.

- ASIC and Surface Packaging Technology

- 316L stainless steel diaphragm construction

- has reverse polarity and current limiting protection

- Laser resistance temperature compensation, zero position adjustable

- Anti-vibration, anti-impact, anti-RF interference

- Overload anti-jamming ability, economic stability, practicability

- range for corrosion resistance, suitable for many cases media

- can be equipped with analog and digital display header

- 2088 head housing

Widely used in various advanced industrial automation environment, involving water conservancy, hydropower, railway traffic, intelligent building, production automation, aerospace, military, petrochemical, oil Wells, power, ships, machine tools, pipelines and many other industries.

- Measuring range: -100kPa... 100MPa

- Measurement medium: gas, liquid, oil and other 316 compatible medium; Pressure type: surface pressure, absolute pressure, sealing pressure, negative pressure;

- Measuring range: -0.1-60MPa;

- Accuracy grade: 0.1, 0.25, 03;

- Overload capacity: 2 times of the range;

- Long-term stability: less than 0.200oFS/ year;

- Power supply: 24VDC;

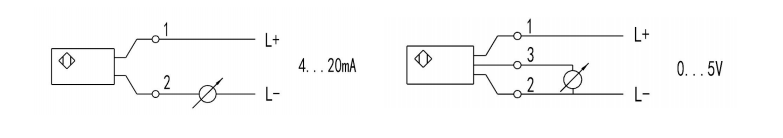

- Output signal: 4~20mA (second/third wire) 0~10/20mA, 0-5V, L ~5V, 0-10V;

- Display mode: 5-digit LCD display;

- Operation mode: built-in =3 button;;;

- Zero migration: through the key to the zero, range migration;

- Working temperature: -40~80℃;

- Compensation temperature: -20~70P;

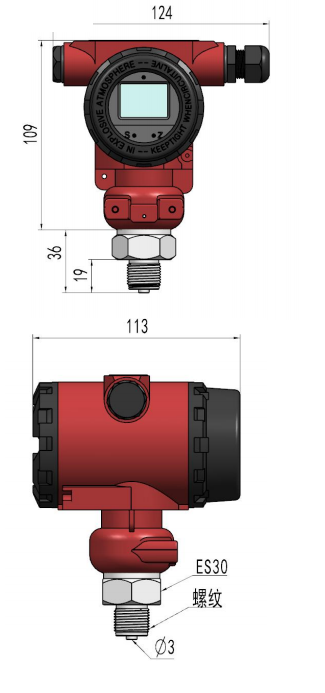

- Process connection: M20x1.5 external thread or user specified;

- Protection grade :IP65;

- Shell material: alloy aluminum; Diaphragm Material

- :ICrl8Ni9Ti.

| specification | ||||||||||||

| PN30D- | PN30D series universal pressure | |||||||||||

| A | absolute pressure | |||||||||||

| B | gage pressure | |||||||||||

| 1 | Range: 100... 0KPa | |||||||||||

| 2 | Range: 100... 100KPa | |||||||||||

| 3 | Range: 100... 500KPa | |||||||||||

| 4 | Range: 0... 6KPa | |||||||||||

| 5 | Range: 0... 35KPa | |||||||||||

| 6 | Range: 0... 70KPa | |||||||||||

| 7 | Range: 0... 100KPa | |||||||||||

| 8 | Range: 0... 200KPa | |||||||||||

| 9 | Range: 0... 500KPa | |||||||||||

| 10 | Range: 0... 1000KPa | |||||||||||

| 11 | Range: 0... 2.5 MPa | |||||||||||

| 12 | Range: 0... 7MPa | |||||||||||

| 13 | Range: 0... 10MPa | |||||||||||

| 14 | Range: 0... 25MPa | |||||||||||

| 15 | Range: 0... 40MPa | |||||||||||

| 16 | Range: 0... 60MPa | |||||||||||

| 17 | Range: 0... 100MPa | |||||||||||

| Customized range: user-defined | ||||||||||||

| A | no display | |||||||||||

| B | With LCD display head | |||||||||||

| 1 | Accuracy grade: 0.5% | |||||||||||

| 4 | 4-20mA analog output | |||||||||||

| 5 | 0-5V voltage output | |||||||||||

| 0 | 0-10V voltage output | |||||||||||

| H | HART | |||||||||||

| 4H | 4-20mA analog output +HART | |||||||||||

| R | 485 communication | |||||||||||

| G2 | Connection mode: G1/2 thread | |||||||||||

| M2 | Connection mode: M20*1.5 thread | |||||||||||

| G4 | Connection mode: G1/4 thread | |||||||||||

| M7 | Connection mode: Flush film M27*2 | |||||||||||

| K | Connection mode: sanitary chuck | |||||||||||

| D... | Connection mode: flange, type D... | |||||||||||

| P | Connection mode: Flush film | |||||||||||

| Custom thread | ||||||||||||

| K | external thread | |||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | ||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Explosion-proof general purpose pressure transmitter-PN30D Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Explosion-proof general purpose pressure transmitter-PN30D Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Explosion-proof general purpose pressure transmitter-PN30D Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .