If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

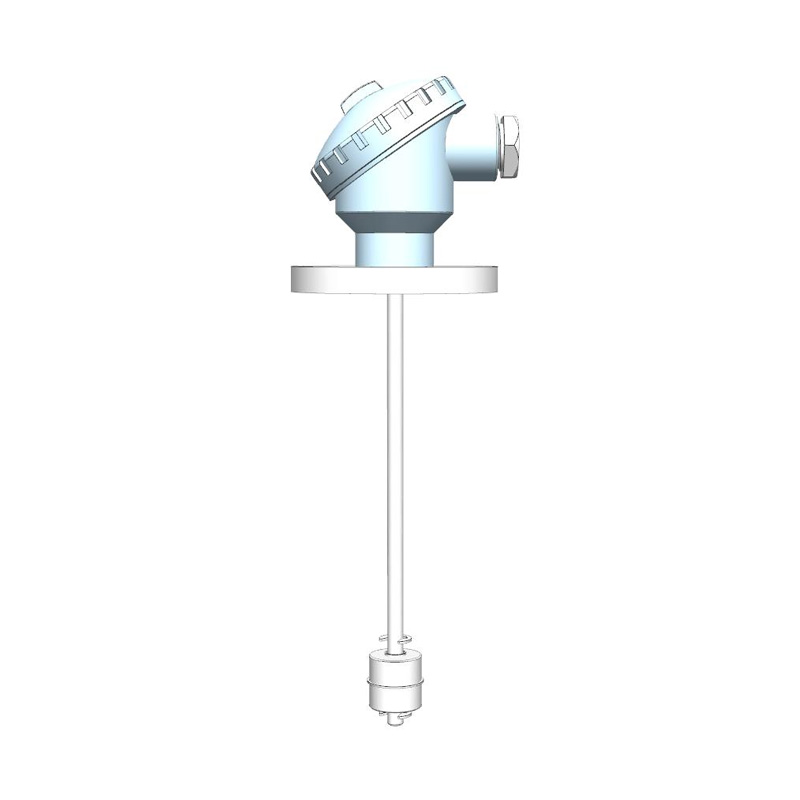

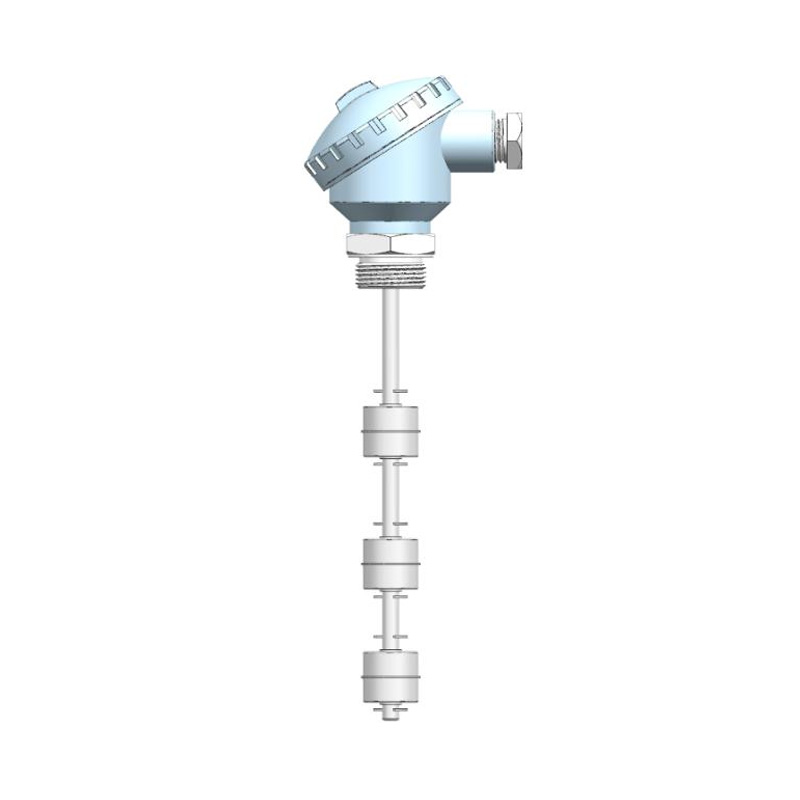

Get couponsFloat Type Liquid Level Switch-LF210

When the liquid level rises or falls, it drives the stainless steel magnetic float ball to move up and down, and the float ball triggers the magnetic spring switch in the detection rod to send a signal.

LF210 series of low price, long life, can be used for liquid level limit monitoring or continuous monitoring. Switching type can provide multi-ball multi-point monitoring, to achieve upper and lower limit alarm or continuous control.

Used for liquid level measurement with density ≥0.75g/cm³

- Maximum pressure: 5bar

- medium temperature: -10℃-130℃

- medium density: ≥0.75g/cm³

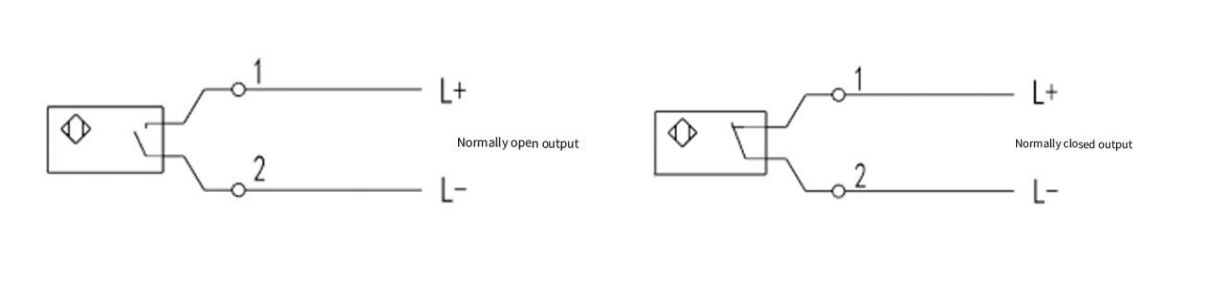

- Output type of switching quantity:

Contact type: Dry reed tube switch

Contact capacity: 250VAC. 0.5A

Output: normally open or normally closed

- Analog output type:

Power supply: 24 ±5% DC

Output: 4-20mA analog quantity

load: ≤750Ω

- Protection grade: IP65

- Wiring mode: terminal

- Material: stainless steel

| LF210- | A | L1 | N | L2 | F | G | X | B | 1 | specification | ||||

| LF210- | LF210 series floating ball level switches | |||||||||||||

| A | monosfera | |||||||||||||

| B | Multi-ball | |||||||||||||

| L1 | Measuring range: specially customized L1= mm | |||||||||||||

| R | Normally open + normally closed | |||||||||||||

| N | normally open | |||||||||||||

| F | normal close | |||||||||||||

| L2 | Measurement range: special custom L2= mm | |||||||||||||

| N | normally open | |||||||||||||

| F | normal close | |||||||||||||

| L3 | Measurement range: special customized L3= mm | |||||||||||||

| N | normally open | |||||||||||||

| F | normal close | |||||||||||||

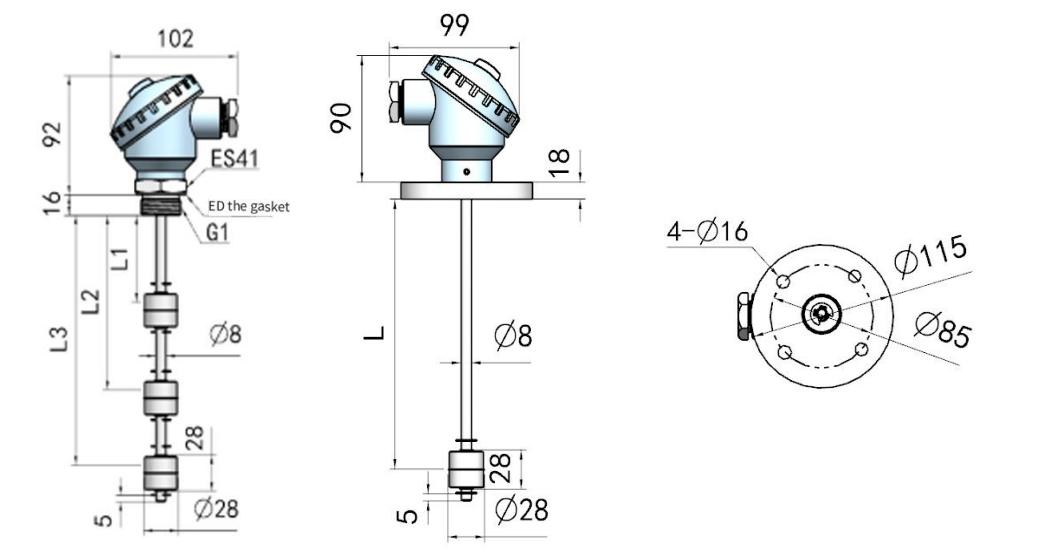

| Installation | E2 | DN25 flanged joint | ||||||||||||

| E5 | DN50flanged joint | |||||||||||||

| G1 | G1RA | |||||||||||||

| G2 | G2RA | |||||||||||||

| X | Installation and connection material: 304 stainless steel | |||||||||||||

| XL | Installation and connection material: 316L stainless steel |

|||||||||||||

| P | Installation connection material: PP polypropylene | |||||||||||||

| XC | Installation and connection material: stainless steel lined tetrafluorine flange |

|||||||||||||

| B | Float material: NBR (φ31) | |||||||||||||

| X1 | Float material: stainless steel (φ28) | |||||||||||||

| X2 | Float material: stainless steel (Φ45) > G1 "thread | |||||||||||||

| F | Float material: anti-corrosion | |||||||||||||

| 1 | general sets | |||||||||||||

| 2 | Explosion-proof device | |||||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | ||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Float Type Liquid Level Switch-LF210 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Float Type Liquid Level Switch-LF210 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Float Type Liquid Level Switch-LF210 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .