If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsUltra-high precision displacement (float level) sensor-LF700

The LF700 series displacement sensor calculates the exact location of the intersecting point of the magnetic field by using the detection time of the strain pulse signal generated when two different magnetic fields intersect. From sensors electronic storehouse of electronic components, a magnetic field generated by the pulse, the pulse of the magnetic field generated along the sensing device inside the rod with high magnetostrictive material waveguide made of silk at the speed of light from end to end, electronic storehouse when and activities of the permanent magnetic field (the permanent magnets general installation on the need to detect position of the moving plate) intersect, due to the magnetostriction phenomenon, A mechanical strain pulse is generated at the intersecting point of the waveguide wire, which is transmitted back to the end of the electron bin at the speed of sound. The strain pulse is detected by the detection circuit in the electron bin. Therefore, the time between transmitting an active pulse wave and receiving a strain pulse wave is the transmission time of sound velocity in the waveguide wire (the operation time of the active wave has been ignored here, and the actual effect is only 0.0001%). Given the speed of sound (the fixed quantity is 3000m/s) and the transmission time, the distance is certainly determined. The above measurements are reconfirmed when the permanent magnet moves to a new position. Therefore, the magnetostrictive displacement sensor has the advantages of high precision, high response, low hysteresis, high reliability, non-contact, long life, high stability, easy installation and so on, without re-calibration, without regular maintenance, so it is widely used in the field of accurate measurement.

servo hydraulic cylinder piston position preset and feedback;

Servo cylinder piston position preset and feedback;

Grinding machine position presetting and feedback;

Casting Forging Machine Position Presetting and Feedback;

Other machinery such as gantry machine position presetting and feedback;

Position presetting and feedback of tunneling machine, shield machine and coal mine machinery cylinder;

Engineering lifting machinery cylinder position presetting and feedback;

Presetting and feedback of steel mill mechanical cylinder position;

Blow cylinder position preset and feedback;

Injection molding machine cylinder position presetting and feedback; u railway, bridge regulation;

Detection of water level, control of sluice;

Wood machinery location presetting and feedback;

Presetting and feedback of tank level;

Chemical container liquid level presetting and feedback;

Drinking water and sewage treatment systems; u geodetic surveying system; Presetting and feedback of valve opening;

measurement of tank level;

Maximum pressure: 5bar

Range: 50~3000mm (hard bar structure), 5000 mm above (soft bar structure).

Linear error: W0.05%FS

repeatability:W0.0005%FS

resolution ratio:W0.001%

slow-moving:W0.001%FS

temperature stability:W0.002%/©

working voltage:+12VDC—+24VDC

working current:W16mA

Working pressure: continuous working pressure 35MPa (MTLL series products)

Working temperature: T1 :-20~+55 °C; T2: - 40 ~ +

85 ° C; T3: - 50 to + 125 ° C

Protection grade: IP67, IP68 (optional)

Explosion-proof mark: EX DII BT5, EXIA II CT5 (must one) can be customized according to customer requirements

output mode: voltage0 - 5 V,0 - 1 0 V

electric current4-20mA, 0-20mA

figure RS485 ,Mudbus

Canbus ,SSI

| LF700- | A | L | N | 1 | C | 1 | specification | ||||

| LF700- | LF700 Series Ultra High Precision Displacement (Float Level) Sensor |

||||||||||

| A | Displacement rod type | ||||||||||

| B | Standard slider type | ||||||||||

| C | Slider rail type | ||||||||||

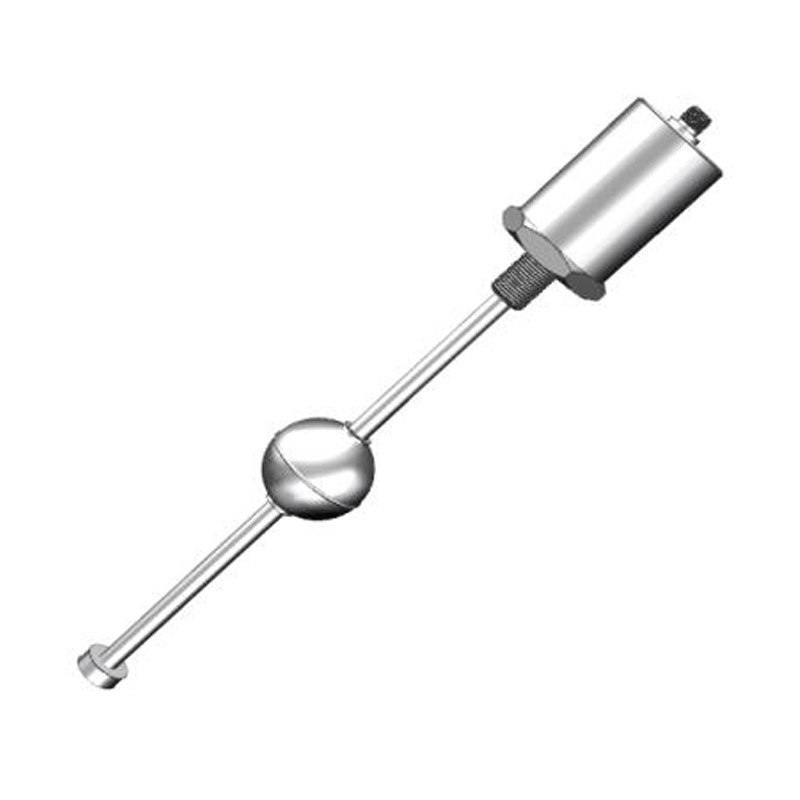

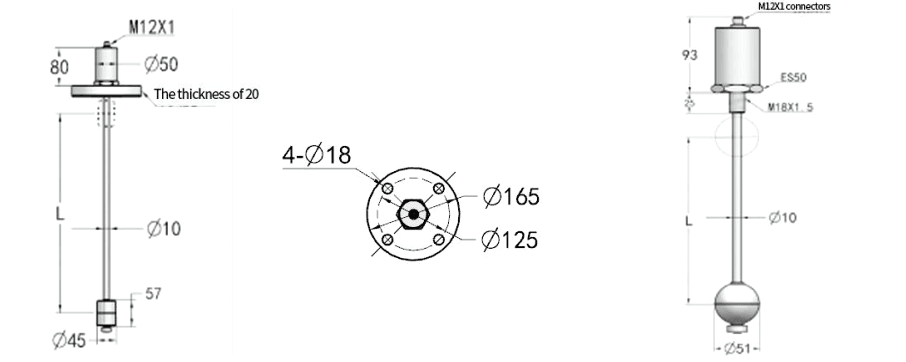

| D | Liquid level float type | ||||||||||

| E | Built-in high pressure flange mounting type | ||||||||||

| F | Suspended slider type | ||||||||||

| G | Built-in high-pressure type | ||||||||||

| H | Removable built-in high pressure type | ||||||||||

| I | Removable liquid level float type | ||||||||||

| L | Effective stroke (mm):50-20000 (Flexible rod is recommended for above 5 meters) |

||||||||||

| N | The magnetic ring moves from the electron bin to the tail end and the value increases |

||||||||||

| S | The magnetic ring moves smaller from the electron bin to the tail end |

||||||||||

| 1 | Output signal: 4-20mA current | ||||||||||

| 2 | Output signal: 0-20mA current | ||||||||||

| 3 | Output signal: 0-5V voltage | ||||||||||

| 4 | Output signal: 0-10V voltage | ||||||||||

| 5 | Output signal: RS485 | ||||||||||

| 6 | output signal:Canbus | ||||||||||

| 7 | output signal:Mudbus | ||||||||||

| 8 | output signal :SSI | ||||||||||

| A | Waterproof cable joint | ||||||||||

| B | Waterproof aviation plug | ||||||||||

| C | Hersman plug | ||||||||||

| 1 | Ordinary-sized | ||||||||||

| 2 | explosion proof type | ||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | |||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Ultra-high precision displacement (float level) sensor-LF700 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Ultra-high precision displacement (float level) sensor-LF700 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Ultra-high precision displacement (float level) sensor-LF700 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .