If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Product 3D Image Get couponsIntelligent Vortex Gas Flow Sensor-SN53D

SN53D series intelligent vortex gas flow sensor is mainly used for flow measurement of industrial pipeline fluid medium. It is characterised by small pressure loss, large range and high accuracy, and is virtually unaffected by fluid density, pressure, temperature, viscosity and other parameters when measuring volumetric flow under working conditions. No moving mechanical parts, so high reliability and low maintenance. The instrument constants are stable over long periods of time.

The instruments use piezoelectric stress sensors, which are highly reliable and can be operated in an operating temperature range of -20°C to +300°C. The instruments are available with analogue standard signals or digital signals. There are analogue standard signals and digital pulse signal output, easy to use with computers and other digital systems, is a more advanced, ideal flow meter.

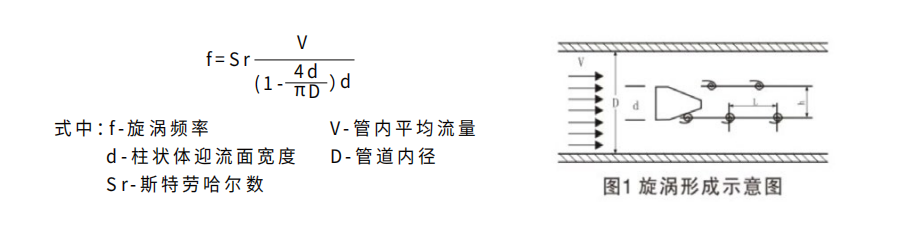

In the fluid vertically inserted into a column of resistance body, on both sides of the vortex will be alternately generated, with the downstream direction of the fluid movement to form a vortex column, known as the Carman vortex street, see Figure 1. vortex street resistance body called vortex generator. Experimentally, the frequency of the vortex is proportional to the flow velocity, which can be expressed by the following formula:

Experimentally, it is proved that the asymmetric vortex column can maintain a stable state when the distance h between two columns of vortices and the distance L between two vortices in the same column satisfy the formula h/L=0.281. When the flow

Reynolds number Re in the range of 5000-150,000, Sr is basically unchanged, so when the column width of the vortex generator d and Strauer Haar number Sr is a fixed value of the frequency of vortex generators

With the average flow rate of the fluid is proportional to the flow rate of Q is proportional to the pressure, temperature, density and other parameters have nothing to do.

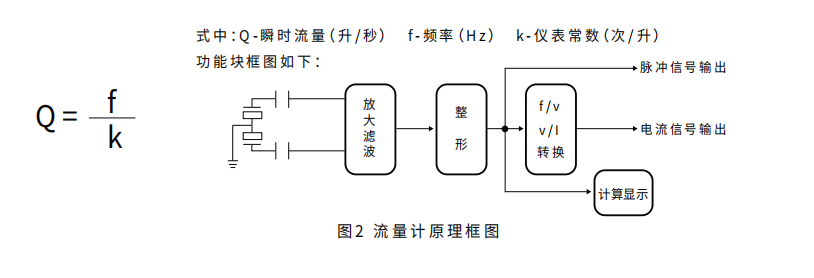

When the vortex generated on both sides of the column, the sensor is perpendicular to the flow direction of the role of alternating lift sensing signal, lift the frequency of change is the vortex frequency, the sensor will be the signal

The sensor will send the signal to the converter to amplify and shape the pulse signal which is linearly proportional to the flow rate, and output it directly or convert it to 4-20mA standard signal output.

The relationship between flow rate Q and frequency f is as follows:

| Connection method | NPT1/2 | |||||||||

| Measuring medium | Gas | |||||||||

| Medium temperature | -10℃~ +80℃ | |||||||||

| Ambient temperature | -20℃~ +45℃ | |||||||||

| Pipe diameter | DN8~ 15mm | |||||||||

| Output signal | 4-20mA(opto-isolated, max load 500 Ω) or RS485 (optically isolated) |

|||||||||

| Power supply | DC24V | |||||||||

| Pipe material | 304 stainless steel | |||||||||

| Pressure level | 1.6MPa | |||||||||

| Gauge Indication | Instantaneous flow rate, cumulative flow rate, standard flow rate, current output value, etc. | |||||||||

| Protection class | IP65 | |||||||||

| Measuring accuracy | ± 1.5% | |||||||||

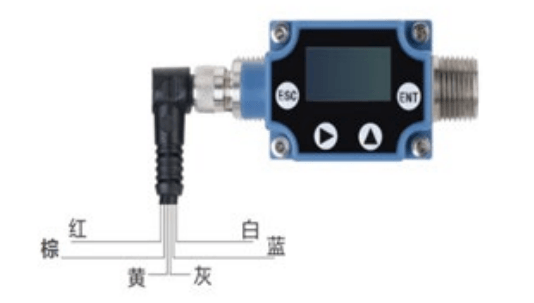

The product adopts DC24V power supply, the instrument has 4-20mA output and RS485 output.

| Red:V+ | Power supply DC24V |

| Brown:V- | |

| Yellow:1+ | 4-20mA output |

| Grey:V- | |

| White:A/D+ | RS485 output |

| Brown:A/B- |

| SN53D- | A | A | 4R | A | P1 | Detailed description | |||||||||||||||

| SN53D- | - | SN53D Series Vortex Gas Flow Sensor | |||||||||||||||||||

| A | With display | ||||||||||||||||||||

| A | Flow range: 1-7m³/H ( DN:8mm ) | ||||||||||||||||||||

| B | Flow range: 2-18m³/H( DN12mm ) | ||||||||||||||||||||

| C | Flow range: 3-30m³/H( DN15mm ) | ||||||||||||||||||||

| 4R | 4-20MA output + RS485 communication | ||||||||||||||||||||

| A | Pipe material: 304 stainless steel | ||||||||||||||||||||

| B | Pipe material: 316L stainless steel | ||||||||||||||||||||

| P1 | Pressure level: 1.6MPA | ||||||||||||||||||||

| Special pressure can be customised | |||||||||||||||||||||

| * The selection table is for parameter selection only, and will be shipped with the corresponding code for the parameter. | |||||||||||||||||||||

Technology Co., Ltd.

en

en English

English Русский

Русский España

España عرب .

عرب .