If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsIntegrated flow temperature sensor-SN10C

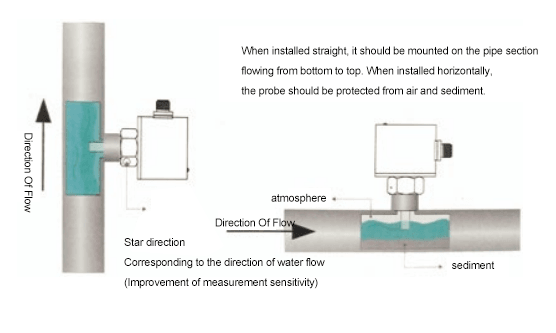

Based on the thermal principle, the sealed probe contains two resistors, one of which is heated to act as a detection resistor and the other unheated to act as a reference resistor. When the medium flows, the heat is carried away from the heated resistor and the resistance value is altered, with the difference between the two resistors being used as the basis for determining the flow rate. At the same time SN10C built-in a PT100 probe or temperature switch, PT100 resistance will change with the media temperature changes or when the temperature reaches the set value, to switch action. No moving parts, maintenance-free, easy to install, a model for a variety of pipe diameter requirements, continuously adjustable switching volume, very low pressure loss, compact structure, LED display flow trend and switching status temperature signal can be optional cabinet-mounted control meter.

Gas-liquid type, low flow rate alarm, and real-time monitoring of the measured medium temperature.

-Setting range:1...150cm/s (water)

3...300cm/s(oil).

20...2000cm/s(air)

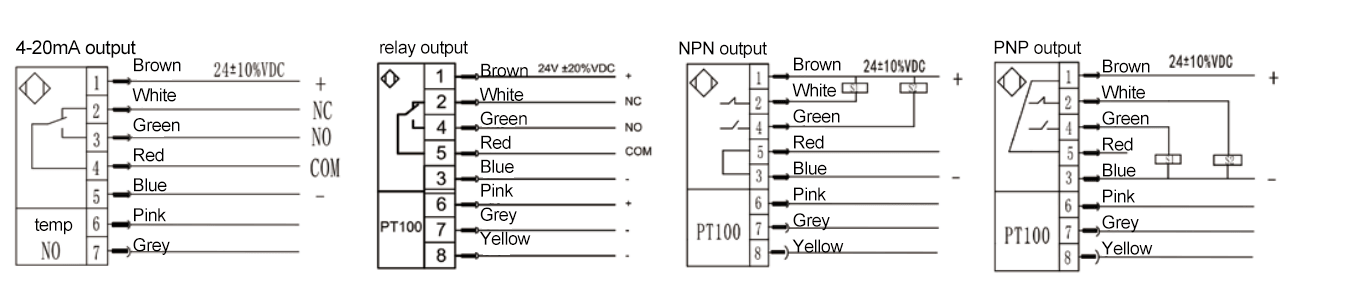

-Signal output: PNP, NPN, relay normally open + normally closed (SPDT)

-Power supply: 24V 20% DC or 230V 15% AC

Turn-on current:Maximum 400mA(PNP or NPN type)

Maximum 1A@48V(Relay type)

-No load current:Max 80mA

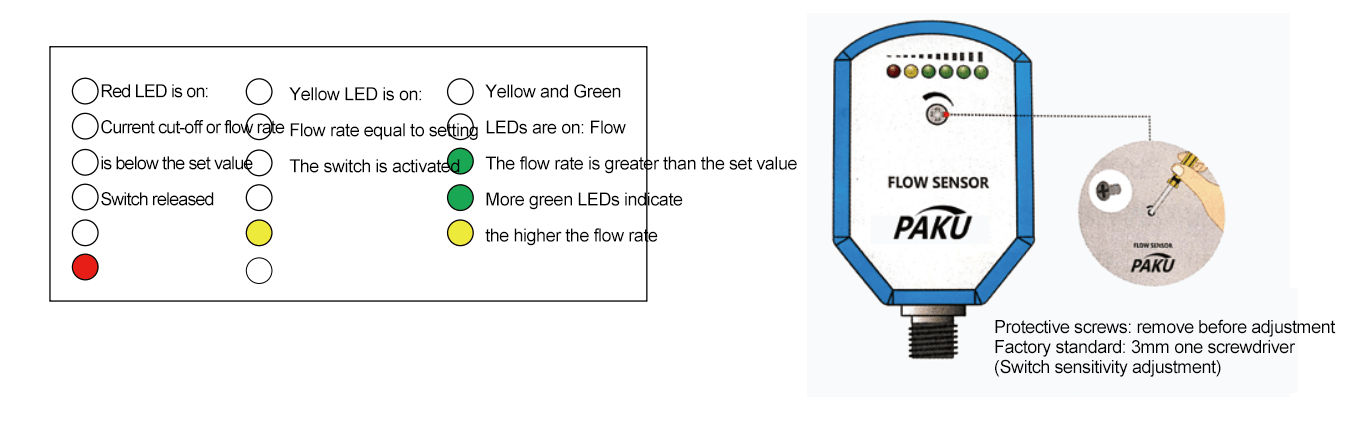

-Flow rate indication: LED row (6pcs)

-Setting method: potentiometer setting

-Pressure resistance range: 100bar

-Temperature gradient: <4°C/S

-Response time: 1-13s, typical value 2s

-Initialisation time: approx. 8s

-Electrical protection: reverse phase, short circuit, overload protection

-Protection level: IP65

-Medium temperature: -20-80°C

-Ambient temperature: -20-80°C

-Storage temperature: -20-100°C

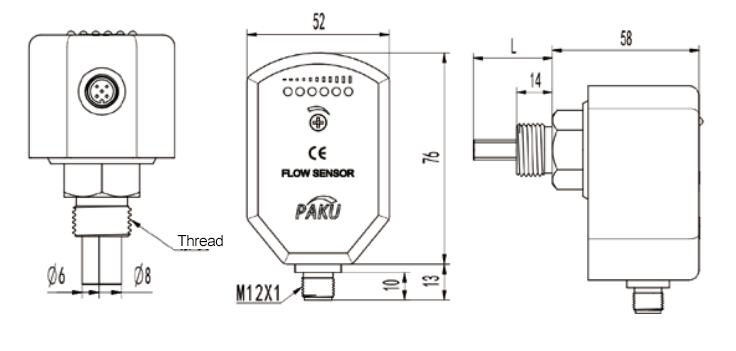

Wiring: M12 connector / directly attached to the 2-metre cable optional

-Material: Probe: stainless steel

Housing:PBT

| SN10C- | G2H | A | 1 | 1 | X | A | 30 | P | Detailing | ||||||||||||

| SN10C- | SN10C Series Integrated Flow Temperature Sensor | ||||||||||||||||||||

| M1K | Interface thread M18*1.5 female (single rod option only) | ||||||||||||||||||||

| G2H | Interface thread G1/2 external thread | ||||||||||||||||||||

| G4H | Interface thread G1/4 male (single rod option only) | ||||||||||||||||||||

| Customised threads, e.g. NPT1/2, option N12 | |||||||||||||||||||||

| A | DC24V±20% power supply | ||||||||||||||||||||

| 1 | PNP output | ||||||||||||||||||||

| 2 | NPN output | ||||||||||||||||||||

| 3 | Relay outputs | ||||||||||||||||||||

| 1 | Normally open + normally closed outputs | ||||||||||||||||||||

| X | Probe material: 304 stainless steel | ||||||||||||||||||||

| XL | Probe material: 316L stainless steel | ||||||||||||||||||||

| A | Plug-in (2 metre cable as standard) | ||||||||||||||||||||

| B | direct line-out | ||||||||||||||||||||

| 30 | Probe length Unit mm (including thread) | ||||||||||||||||||||

| L | Customised probe length in mm (including threads) | ||||||||||||||||||||

| P | PT100 resistance signal output (3-wire) | ||||||||||||||||||||

| 4 | 4-20mA output | ||||||||||||||||||||

| NO | Temperature normally open output, e.g. 50 degrees normally open, option: NO50 | ||||||||||||||||||||

| NC | Temperature normally closed output e.g. 50 degrees normally closed, option: NC50 | ||||||||||||||||||||

| * Factory standard electrical accessories M12 connector type ZL08-PU02FG * M18*1.5 female threaded rod length including thread 60mm mounting method, please pay attention to the optional mounting accessories. * Customised threads are available, H is male thread and K is female thread. * Electrical accessories and mounting accessories, please see the accessories page. * The selection table is for parameter selection only, and the corresponding code of the parameter will be shipped from the factory. |

|||||||||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Integrated flow temperature sensor-SN10C Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Integrated flow temperature sensor-SN10C Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Integrated flow temperature sensor-SN10C Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .