If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Product 3D Image Get couponsVortex flowmeter-SN58

SN58 series precession vortex flowmeter integrates the function of flow, temperature and pressure detection, and can automatically compensate the temperature, pressure and compression factor. It is an ideal instrument for gas metering in petroleum, chemical, electric power, metallurgy and other industries.

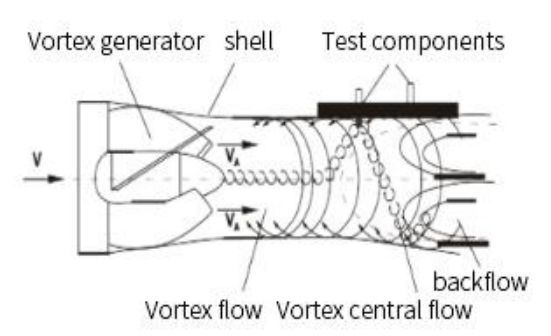

The flow profile of the flow sensor is similar to the profile of a Venturi tube (as shown in the figure). A group of spiral guide vanes is placed at the entrance side. When the fluid enters the flow sensor, the guide vanes force the fluid to produce intense eddy flow. When the fluid enters the diffusion section, the vortex flow is affected by the backflow and begins to rotate twice, forming the phenomenon of gyroscopic vortex precession. The precession frequency is proportional to the flow rate and is not affected by the physical properties and density of the fluid. If the second rotation precession frequency of the fluid is measured by the detection element, good linearity can be obtained in a wide flow range. The signal is amplified by the preamplifier, filtered, and transformed into pulse signals proportional to the flow rate, and then sent to the microprocessor for integration processing together with the temperature and pressure test signals. Finally, the measurement results (instantaneous flow, cumulative flow, temperature and pressure data) are displayed on the LCD screen.

Widely used in petroleum, chemical, electric power, metallurgy, urban gas supply and other industries to measure a variety of gas flow, is the current oil and city gas transmission and distribution metering and trade metering of the first choice of products.

No mechanical moving parts, not easy to corrosion, stable and reliable, long life, long operation without special maintenance;

- Using 16-bit computer chip, high integration, small size, good performance, the machine function is strong;

u Intelligent flowmeter integrates flow probe, microprocessor, pressure and temperature sensor in one, adopts built-in combination, makes the structure more compact, can directly measure the flow rate, pressure and temperature of the fluid, and automatic real-time tracking compensation and compression factor correction;

- The dual detection technology can effectively improve the detection signal strength and suppress the interference caused by pipeline vibration.

- Adopts the domestic leading intelligent anti-seismic technology, effectively inhibits the interference signal caused by vibration and pressure fluctuation;

- Adopt Chinese dot matrix display screen, display number is many, the reading is intuitive and convenient, can directly display the volume flow under the working state, the volume flow under the standard state, the total volume, to and the medium pressure, temperature and other parameters;

- Using EEPROM technology, convenient parameter setting, can be permanently stored, and can save up to one year of historical data;

- converter can output frequency pulse, 4 ~ 20mA analog signal, and has RS485

- Interface, can be directly networked with microcomputer, transmission distance up to 1.0km;

- Multi-physical parameter alarm output, one of which can be selected by users;

- The head of the flowmeter can rotate 360 degrees, easy to install and use;

- with the company's FM data collector, can be through the Internet or telephone network for remote data transmission

- Pressure and temperature signal for sensor input mode, strong interchangeability;

- The whole machine has low power consumption and can be powered by internal battery or external power supply。

| Meter diameter | 15mm、20mm、25mm、32mm、40mm、50mm、65mm、 80mm、100mm、125mm、150mm、200mm |

||||||||||||||||||

| nominal pressure | 1.6MPa、2.5MPa、4.0MPa | ||||||||||||||||||

| compensation | Double temperature and pressure compensation | ||||||||||||||||||

| output signal | Pulse, 4-20mA, RS485, IC card signal | ||||||||||||||||||

| communication protocol | Modbus-RTU, HART (custom made) | ||||||||||||||||||

| power supply | 1. External 24VDC DC power supply. 2、Battery-powered, 3.6 lithium batteries. |

||||||||||||||||||

| service conditions | Medium temperature :-20 °C-80 °C Ambient temperature :-30 °C-60 °C Relative humidity :5%-90% Atmospheric pressure :86kPa-106kPa |

||||||||||||||||||

| Protection grade |

IP65、IP67 | ||||||||||||||||||

| anti-hazard classification |

Ex ia IIC T6 Ga | ||||||||||||||||||

| applicable medium | Natural gas, compressed air, nitrogen and other low flow rate gas | ||||||||||||||||||

| Range than | 1 : 10-1 : 15 | ||||||||||||||||||

| accuracy | 1.0、1.5 | ||||||||||||||||||

| Material | Aluminum Alloy/Stainless Steel | ||||||||||||||||||

| product standard | SY 6658-2006 | ||||||||||||||||||

| installation direction | Install horizontally or vertically | ||||||||||||||||||

| Nominal diameter DN( mm ) |

range of flow (m3/ h) |

working pressure ( MPa ) |

accuracy class | repeatability | |||||||||||||||

| 15 | 1.0-10 | 1.6 2.5 4.0 6.3 |

1.0 1.5 |

Less than the absolute value of the fundamental error limit 1/3 |

|||||||||||||||

| 20 | 1.5-15 | ||||||||||||||||||

| 25 | 3.0-30 | ||||||||||||||||||

| 32 | 6.0~60 | ||||||||||||||||||

| 40 | 7.0~70 | ||||||||||||||||||

| 50 | 12~ 150 | ||||||||||||||||||

| 65 | 20~300 | ||||||||||||||||||

| 80 | 40~400 | ||||||||||||||||||

| 100 | 80~900 | ||||||||||||||||||

| 125 | 80-1000 | ||||||||||||||||||

| 150 | 150~ 1500 | ||||||||||||||||||

| 200 | 240~3600 | 1.6;2.5;4.0 | |||||||||||||||||

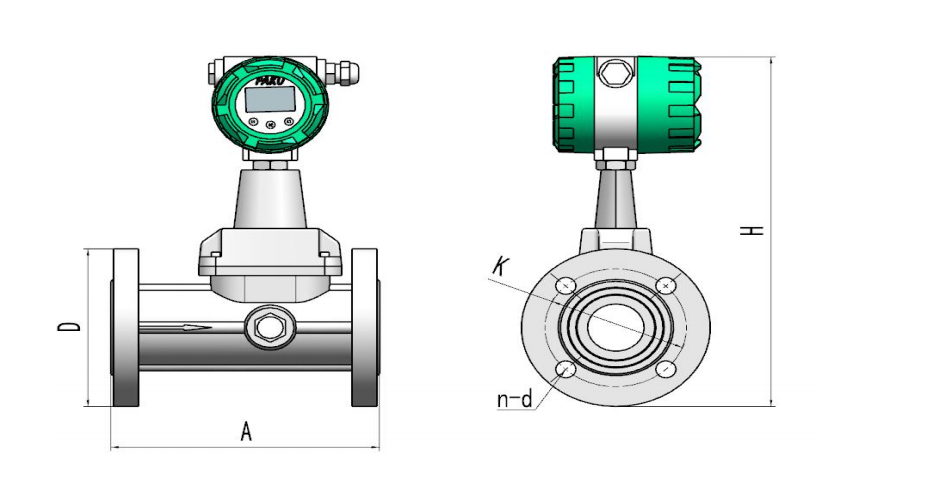

| nominal diameter DN(mm) |

nominal pressure (MPa) |

boundary dimension( mm ) | The table body material | weight (kg) |

|||||||||||||||

| The length of the table A |

altitude H |

stainless steel | aluminium alloy | ||||||||||||||||

| 20 | 1.6/2.5/4.0 | 160 | 360 | √ | √ | 6 | |||||||||||||

| 6.3/10/16 | 160 | 365 | √ | 8 | |||||||||||||||

| 25 | 1.6/2.5/4.0 | 180 | 367 | √ | √ | 7 | |||||||||||||

| 6.3/10/16 | 180 | 378 | √ | 10 | |||||||||||||||

| 32 | 1.6/2.5/4.0 | 200 | 383 | √ | √ | 9 | |||||||||||||

| 6.3/10/16 | 200 | 402 | √ | 12 | |||||||||||||||

| 40 | 1.6/2.5/4.0 | 230 | 383 | √ | √ | 9 | |||||||||||||

| 6.3/10/16 | 230 | 402 | √ | 12 | |||||||||||||||

| 50 | 1.6/2.5/4.0 | 230 | 403 | √ | 9 | ||||||||||||||

| 6.3/10/16 | 230 | 421 | √ | 14 | |||||||||||||||

| 65 | 1.6/2.5/4.0 | 285 | 421 | √ | 11 | ||||||||||||||

| 6.3/10/16 | 285 | 438 | √ | 14 | |||||||||||||||

| 80 | 1.6 | 330 | 438 | √ | √ | 14 | |||||||||||||

| 2.5/4.0 | 330 | 438 | √ | 18 | |||||||||||||||

| 6.3/10/16 | 330 | 446 | √ | 21 | |||||||||||||||

| 100 | 1.6 | 410 | 468 | √ | √ | 14 | |||||||||||||

| 2.5/4.0 | 410 | 475 | √ | 18 | |||||||||||||||

| 6.3/10/16 | 410 | 483 | √ | 33 | |||||||||||||||

| 150 | 1.6 | 585 | 542 | √ | √ | 21 | |||||||||||||

| 2.5/4.0 | 585 | 549 | √ | 52 | |||||||||||||||

| 6.3/10/16 | 585 | 572 | √ | 72 | |||||||||||||||

| 200 | 1.6 | 700 | 618 | √ | √ | 41 | |||||||||||||

| 2.5 | 700 | 626 | √ | 117 | |||||||||||||||

| 4.0 | 700 | 634 | √ | 127 | |||||||||||||||

| SN58- | A | A | 4 | B4 | A | D | specification | ||||||||||||

| SN58- | SN58 series precession vortex flowmeter | ||||||||||||||||||

| A | ordinary type | ||||||||||||||||||

| B | flame-proof type | ||||||||||||||||||

| C | Economical stand-alone version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||

| D | Precision stand-alone version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||

| E | Precision network version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||

| A | Range: 1.0-10m³/H (corresponding pipeline: DN15) | ||||||||||||||||||

| B | Range: 1.5-15m³/H (corresponding pipeline: DN20) | ||||||||||||||||||

| C | Range: 3.0-30m³/H (corresponding pipeline: DN25) | ||||||||||||||||||

| D | Range: 6.0 ~ 60m³/H (corresponding pipeline: DN32) | ||||||||||||||||||

| E | Range: 7.0 ~ 70m³/H (corresponding pipeline: DN40) | ||||||||||||||||||

| F | Range: 12 ~ 150m³/H (corresponding pipeline: DN50) | ||||||||||||||||||

| G | Range: 20 ~ 300m³/H (corresponding pipeline: DN65) | ||||||||||||||||||

| H | Range: 40 ~ 400m³/H (corresponding pipeline: DN80) | ||||||||||||||||||

| I | Range: 80 ~ 900m³/H (corresponding pipeline: DN100) | ||||||||||||||||||

| J | Range: 80-1000m³/H (corresponding pipeline: DN125) | ||||||||||||||||||

| K | Range: 150 ~ 1500m³/H (corresponding pipeline: DN150) | ||||||||||||||||||

| L | Range: 240 ~ 3600m³/H (corresponding pipeline: DN200) | ||||||||||||||||||

| 4 | 4-20 ma output | ||||||||||||||||||

| C | pulse output | ||||||||||||||||||

| R | RS485 output | ||||||||||||||||||

| CR | Equivalent pulse output +RS485 output | ||||||||||||||||||

| M | MODBUS-RTU( customization ) | ||||||||||||||||||

| H | HART( customization ) | ||||||||||||||||||

| B16 | Pressure resistance: 16bar, selection B16 | ||||||||||||||||||

| B25 | Pressure resistance: 25bar, type B25 | ||||||||||||||||||

| B40 | Pressure resistance: 40bar, type B40 | ||||||||||||||||||

| B63 | Pressure resistance: 63bar, type B63 | ||||||||||||||||||

| B... | Custom compression | ||||||||||||||||||

| A | Accuracy: grade 1.0 | ||||||||||||||||||

| B | Accuracy: Level 1.5 | ||||||||||||||||||

| D | External 24VDC DC power supply | ||||||||||||||||||

| C | Battery powered, 3.6 lithium battery | ||||||||||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | |||||||||||||||||||

Technology Co., Ltd.

en

en English

English Русский

Русский España

España عرب .

عرب .