If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Product 3D Image Get couponsUltrasonic Flow Meter-SN53A

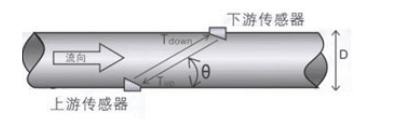

SN53A series ultrasonic flowmeter and analyser adopts the measurement principle of time difference method. It uses the sensor to send ultrasonic propagation in the flowing fluid, downstream direction of the sound wave propagation speed will increase, against the direction of the flow is reduced, in the same propagation distance there are different transmission time, according to the difference between the transmission time and the measured fluid flow rate of fluid flow rate is measured in relation to the fluid flow rate.

Fluid flow velocity is different at different locations in the pipe, and the flow velocity in the centre of the pipe is faster than the flow velocity near the pipe wall. The distribution of the flow velocity of a fluid in a pipe can be represented by a cross sectional distribution of the flow velocity. By setting up the flow meter and considering the effect of the cross-sectional distribution of the flow velocity, it is possible to calculate the average flow velocity and then derive the volume flow rate of the fluid based on the cross-sectional area of the pipe.

Central air-conditioning, washing machine, tap water, modern agricultural irrigation, garden irrigation, production process water, industrial recycled water, water, pure water/ultrapure water, bathing industry, swimming pool, laundry industry, etc.

-Flow rate range:0.3~5m/s

-Accuracy:earth 2%

-Repeatability:0.4%

-Keyboard:3 light touch switch keys

-Display:OLED display

Resolution:128*128

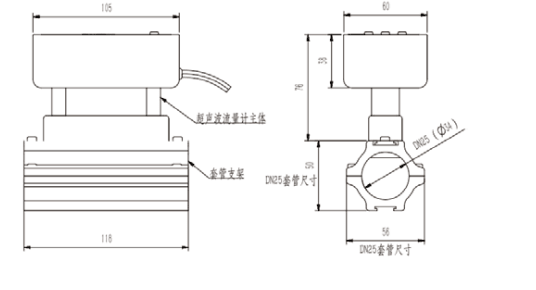

-Mounting:Pipe clamp screw fastening

-Power Consumption:5W (depending on function)

-Power supply:10~36VDC/500mA

-Shell material: ABS

-Measuring Pipe:Stainless Steel Pipe/Copper Pipe

PVC pipe/carbon steel pipe

- Measuring medium temperature:0~100°C

-Output interface: 4-20mA output

-Communication interface:RS485

- WIFI: Support

-Bluetooth:support

-Protection level:1P55

-Ambient temperature:0~60°C

-Cable length:2m

V:Fluid velocity

M:Ultrasonic reflection times

D:pipe diameter

0:Angle between ultrasonic signal and fluid

Tup:Time from downstream transducer to upstream transmitting signal

Tdown:time from upstream sensor to downstream sensor

Δ=Tdown-Tup

-No need to break the pipe to install

-Measures without adjustment

-Permanent and resettable accumulation

-RS-485 communication interface

-OLED display

-Protection rating up to IP55

-Flow control and monitoring

-Calculation of fluid totals

-Water distribution

-Leakage monitoring

-Wifi connection

-Bluetooth settings

| Pipe Material | Pipe Nominal Inner Diameter |

Pipe Clamps for Pipe O.D. Range (mm) |

Flow range (0.03~5m/s) (m3/h) |

|||||||||||||

| PVC/stainless steel/carbon steel | DN20 | 25~29 | 0.04~6 | |||||||||||||

| Copper | ||||||||||||||||

| PVC/stainless steel/carbon steel | DN25 | 32~36 | 0.05~9 | |||||||||||||

| Copper | 25~29 | |||||||||||||||

| PVC/stainless steel/carbon steel | DN32 | 39~43 | 0.09~15 | |||||||||||||

| Copper | 32~36 | |||||||||||||||

| PVC/stainless steel/carbon steel | DN40 | 50~54 | 0.13~23 | |||||||||||||

| Copper | 39~43 | |||||||||||||||

| PVC/stainless steel/carbon steel | DN50 | 63~67 | 0.20~35 | |||||||||||||

| Copper | 50~54 | |||||||||||||||

| PVC/stainless steel/carbon steel | DN65 | 76~80 | 0.35~60 | |||||||||||||

| Copper | 63~67 | |||||||||||||||

| PVC/stainless steel/carbon steel | DN80 | 87~91 | 0.55~90 | |||||||||||||

| Copper | 76~80 | |||||||||||||||

| SN53A | - | Detailed description | ||||||||||||||

| SN53A | - | SN53A series ultrasonic flowmeter | ||||||||||||||

| 20 | Nominal inner diameter of pipe: DN20 | |||||||||||||||

| 25 | Nominal inner diameter of pipe: DN25 | |||||||||||||||

| 32 | Nominal inner diameter of pipe: DN32 | |||||||||||||||

| 40 | Nominal inner diameter of pipe: DN40 | |||||||||||||||

| 50 | Nominal inner diameter of pipe: DN50 | |||||||||||||||

| 65 | Nominal inner diameter of pipe: DN65 | |||||||||||||||

| 80 | Nominal inner diameter of pipe: DN80 | |||||||||||||||

| A | Pipe material: PVC | |||||||||||||||

| B | Pipe material: stainless steel | |||||||||||||||

| C | Pipe Material: Carbon Steel | |||||||||||||||

| Pipe Material: Copper | ||||||||||||||||

| R | RS485 | |||||||||||||||

| 4 | 4-20mA | |||||||||||||||

Technology Co., Ltd.

en

en English

English Русский

Русский España

España عرب .

عرب .