If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsThermal Gas Mass Flow Meter-SN50A

SN50A series thermal gas mass flowmeter is the use of the principle of heat conduction flow measurement instrument.The instrument uses the method of constant temperature difference to accurately measure the mass flow of gas.It has the advantages of small size, high degree of digitalization, convenient installation and accurate measurement.The sensor part consists of two benchmark platinum resistance temperature sensors.With a bridge loop, one sensor measures the flow temperature and the other maintains a thermostatic difference above the fluid temperature, allowing flow measurements under high temperature and pressure conditions. Real mass flowmeter, gas flow measurement without temperature and pressure compensation, measurement is convenient and accurate.The mass flow rate or standard volume flow rate of the gas can be obtained. Wide range ratio, can measure the gas flow rate up to 100Nm/s bottom to 0.5nm /s, can be used for gas leak detection.good seismic performance long service life.The sensor has no moving parts and pressure sensing parts and is not affected by vibration to the measurement accuracy. Easy to install and maintain.If site conditions permit, installation and maintenance without stopping production can be realized.(See Safety Precautions) Digital design.The whole digital circuit measurement, accurate measurement, easy maintenance. Adopt RS-485 communication, or HART communication, can realize factory automation, integration.

| The connection method |

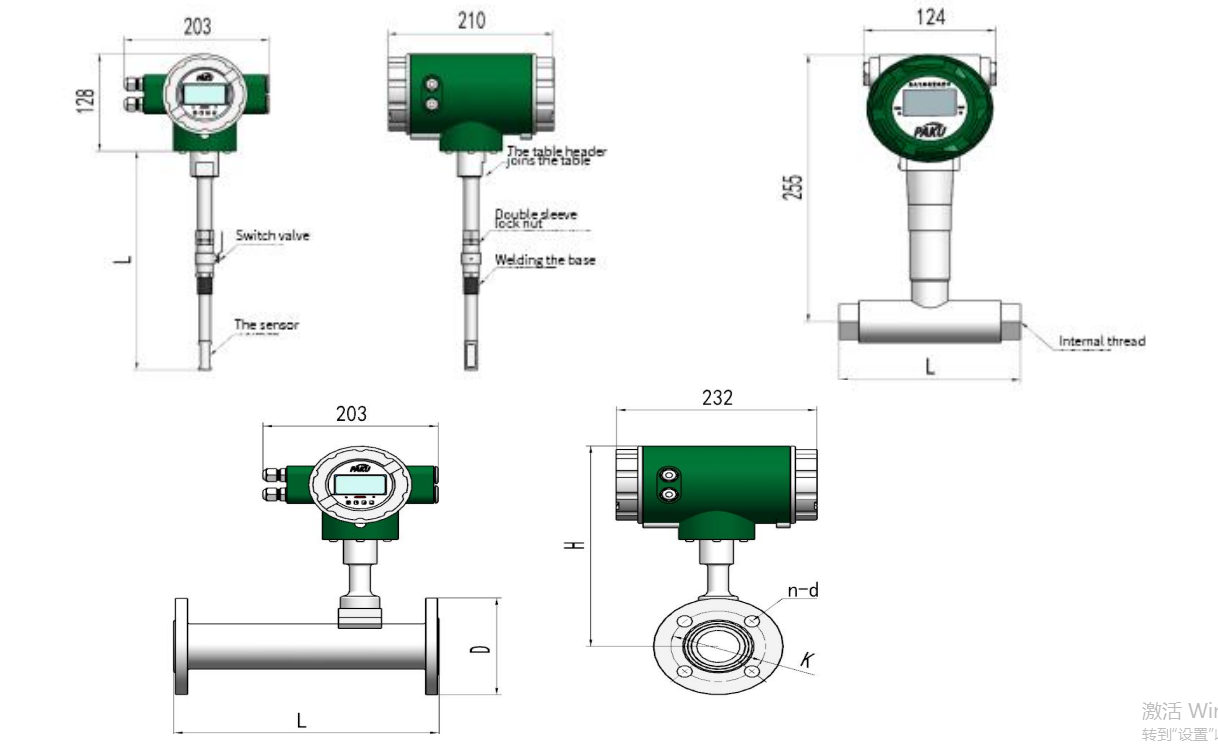

flange form DN25~ 150mm screw-type DN25~50mm plug-in DN125〜5000mm |

||||||||||||||||||||||||||

| Measuring the dielectric |

Single component or compartment-stable mixed dry gases (except B block gas and oxygen) | ||||||||||||||||||||||||||

| medium temperature | (1 ) -10°C- + 100°C (2) -10°C- +200C | ||||||||||||||||||||||||||

| The environment | 一20°C~ +45°C | ||||||||||||||||||||||||||

| Pipe size | DN25~5000mm | ||||||||||||||||||||||||||

| The output signal | (1) 4-20mA (photoelectric isolation, maximum load of 500 Q), pulse, RS485 (photoelectric isolation), HART protocol | ||||||||||||||||||||||||||

| Alarm output | (1) 1-2 circuit relay normally open contact, (10A/220V/AC, 5A/30V/DC) | ||||||||||||||||||||||||||

| Power supply | ( 1 )DC24V ( 2 )AC220V ( 3 )18 w w power consumption | ||||||||||||||||||||||||||

| Tube | (1) 304 stainless steel (2) 316 stainless steel | ||||||||||||||||||||||||||

| pressure rating | P2=1.6MPa (standard)DN125~5000mm insert type P2=1.6MPa (standard)DN25~ 150mm flange type, DN25~ 50mm thread type P3= 2.5Mpa (special)DN25 ~ 100mm flange type P4= 4.0Mpa (special)DN25 ~ 100mm flange type |

||||||||||||||||||||||||||

| Header indicating | Standard volume instantaneous flow, cumulative flow, standard flow rate, current output value, etc | ||||||||||||||||||||||||||

| level of protection | IP65 | ||||||||||||||||||||||||||

| measurement accuracy | ±(1.5+0.5FS) % | ||||||||||||||||||||||||||

| Medium flow rate | General: 0.56~56Nm/s, the maximum flow rate can be extended to 100 Nm/s (range width can be negotiated for order) | ||||||||||||||||||||||||||

| note | Front N20DN and rear N10DN are required for straight pipe segments. For example, 90°C elbow or pipe expansion, please refer to the instructions for details |

||||||||||||||||||||||||||

| Threaded DN15~25mm range gauge | ||

| DN | minimum discharge (Nm³/h) |

maximum flow (Nm³/h) |

| 15(G 72") | 0.3 | 30 |

| 20(G 74") | 0.5 | 50 |

| 25(G") | 1 | 100 |

| Flanged DN25~150mm range gauge | ||

DN (mm) |

minimum discharge (Nm³h) |

maximum flow (Nm³h) |

| 25 | 1 | 100 |

| 32 | 1.5 | 150 |

| 40 | 2 | 250 |

| 50 | 4 | 400 |

| 65 | 6.5 | 650 |

| 80 | 10 | 1000 |

| 100 | 15 | 1500 |

| 125 | 25 | 2500 |

| 150 | 35 | 3500 |

| DN (mm) |

minimum discharge (Nm³h) |

maximum flow (Nm³h) |

DN (mm) |

minimum discharge (Nm³h) |

maximum flow (Nm³h) |

| 50 | 4 | 400 | 800 | 1000 | 100000 |

| 65 | 6.5 | 650 | 900 | 1300 | 130000 |

| 80 | 10 | 1000 | 1000 | 1600 | 160000 |

| 100 | 15 | 1500 | 1100 | 1950 | 195000 |

| 125 | 25 | 2500 | 1200 | 2280 | 228000 |

| 150 | 35 | 3500 | 1300 | 2680 | 268000 |

| 125 | 25 | 2500 | 1400 | 3100 | 310000 |

| 150 | 35 | 3500 | 1500 | 3560 | 356000 |

| 200 | 65 | 6500 | 1600 | 4050 | 405000 |

| 250 | 100 | 10000 | 1700 | 4560 | 456000 |

| 300 | 150 | 15000 | 1800 | 5150 | 515000 |

| 350 | 200 | 20000 | 1900 | 5750 | 575000 |

| 400 | 250 | 25000 | 2000 | 6350 | 635000 |

| 450 | 320 | 32000 | 2500 | 9500 | 950000 |

| 500 | 400 | 40000 | 3000 | 14000 | 1400000 |

| 550 | 480 | 48000 | 3500 | 19000 | 1900000 |

| 600 | 560 | 56000 | 4000 | 24000 | 2400000 |

| 650 | 680 | 68000 | 4500 | 30000 | 3000000 |

| 700 | 780 | 78000 | 5000 | 38000 | 3800000 |

| nominal diameter DN |

pressure rating MPa |

contour length L |

height of contour H |

center | flange outer diameter | tap n-d |

thread specification | Flange thickness B | |||||||||||||||||||

| 25 | 1.6 | 305 | 320 | 85 | 115 | 4x 014 | M12 | 16 | |||||||||||||||||||

| 32 | 1.6 | 310 | 324 | 100 | 140 | 4 x 018 | M16 | 18 | |||||||||||||||||||

| 40 | 1.6 | 320 | 327 | 110 | 150 | 4 x 018 | M16 | 18 | |||||||||||||||||||

| 50 | 1.6 | 396 | 332 | 125 | 165 | 4 x 018 | M16 | 20 | |||||||||||||||||||

| 65 | 1.6 | 410 | 340 | 145 | 185 | 4x 018 | M16 | 20 | |||||||||||||||||||

| 80 | 1.6 | 420 | 348 | 160 | 200 | 8x 018 | M16 | 20 | |||||||||||||||||||

| 100 | 1.6 | 457 | 360 | 180 | 220 | 8x 018 | M16 | 22 | |||||||||||||||||||

| 125 | 1.6 | 500 | 372 | 210 | 250 | 8 x(P18 | M16 | 22 | |||||||||||||||||||

| 150 | 1.6 | 500 | 387 | 240 | 285 | 8x 022 | M20 | 24 | |||||||||||||||||||

| SN50A | A | DN | A | 2 | 4 | D | A | detailed |

| SN50A- | SN50A series themal gas mass flowmeter | |||||||

| A | Thread-forming screw | |||||||

| B | flange form | |||||||

| C | plug-in | |||||||

| DN | Size,e.g.DN25,Type 25(Refer to Range | |||||||

| A | Normal temperature:-10..100 ℃ | |||||||

| B | High temperature style:0...200℃ | |||||||

| 2 | Two-way switching quantity (relay) | |||||||

| 4 | 4-20 ma output | |||||||

| C | Pulse output | |||||||

| R | RS485 communication | |||||||

| H | HART protocol | |||||||

| D | Power supply:24V DC | |||||||

| A | Power supply:220V AC | |||||||

| A | Pressure withstand:1.6MPa (standard) | |||||||

| B | Pressure withstand:2.5MPa(special) | |||||||

| C | Pressure withstand:4.0MPa(special) | |||||||

| *The selection table is only available for parameter selection,and the corresponding code is delivered. | ||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Thermal Gas Mass Flow Meter-SN50A Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Thermal Gas Mass Flow Meter-SN50A Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Thermal Gas Mass Flow Meter-SN50A Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .