If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

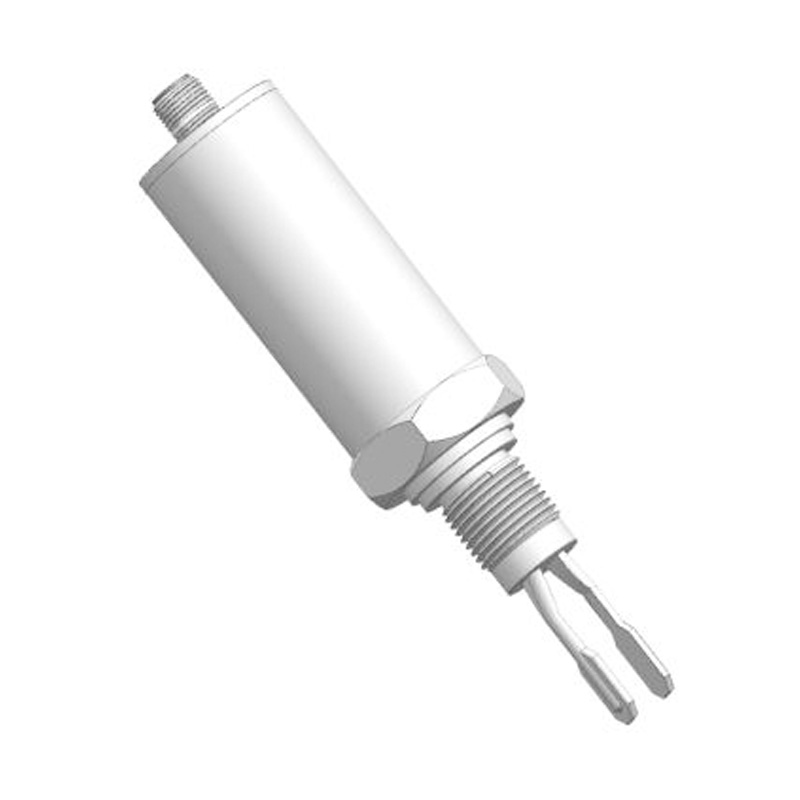

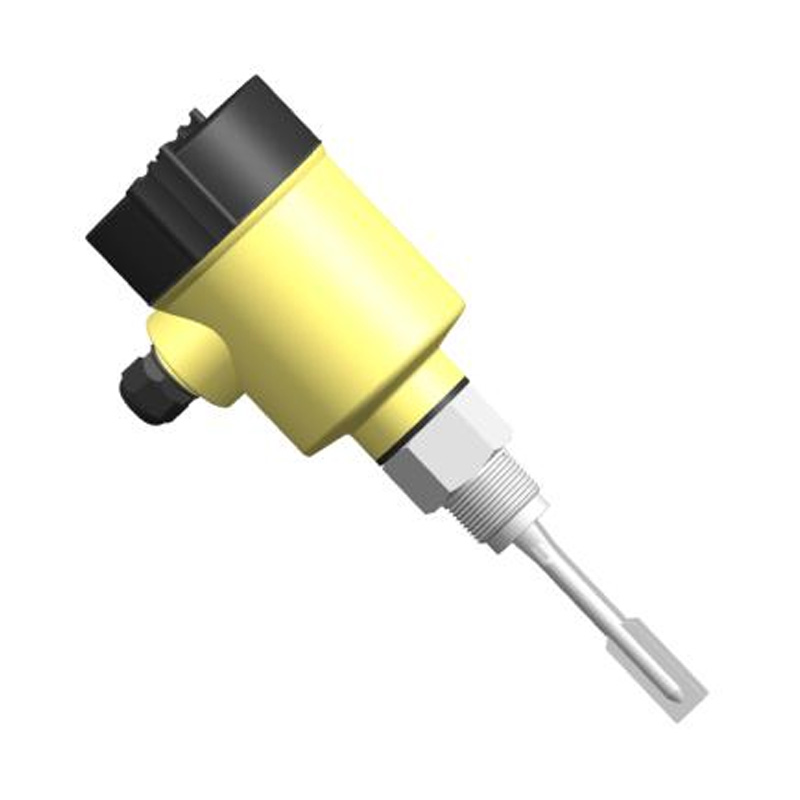

Get couponsTuning fork level switch-LF100

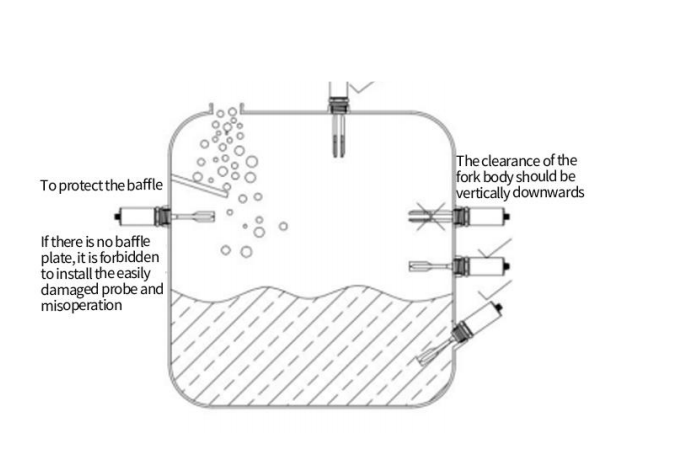

LF100 series tuning fork type material level limit switch is a kind of universal material level limit switch. Inspired by piezoelectric crystal a tuning fork produces an oscillation, when the tuning fork is liquid or solid immersion vibration frequency change, change the frequency by the electronic circuit electric parameters detected from the media and the turbulent, agitation, bubble, vibration, the influence of such factors as no moving parts, so no maintenance amount adjustment, is the ideal choice of the material level switch under complicated conditions.

- Hydraulic/Lubrication

- Pump protection cooling system pulp

- water treatment

- food and beverage

- No moving parts

- is not affected by the density and electrical parameters of the medium

- stainless steel contact parts

- AC/DC power supply is optional

- relay output

- Normally onand normallyoff can beswitched

- can be used for solid or liquid measurement

- Two electronic heads available (compact/rugged)

| Measuring Media | Liquid or solid particles | ||||||

| density measurement | ≥0.6g/cm³ | ||||||

| withstand voltage | 20bar | ||||||

| Adjustable time delay | 1... 20S (Rugged only) | ||||||

| response time | 1s | ||||||

| DC supply type | 24 ±10%Vdc | ||||||

| AC powered type | 110 vac or 220 vac | ||||||

| power dissipation | ≤1W | ||||||

| switched output | |||||||

| The output type | Relay (normally open, normally | ||||||

| load capacity | AC220V( 110V)/3A,DC | ||||||

| Wiring protection | opposition | ||||||

| temperature | |||||||

| operating | -20...80℃ | ||||||

| medium temperature | -40...150℃ | ||||||

| materials | |||||||

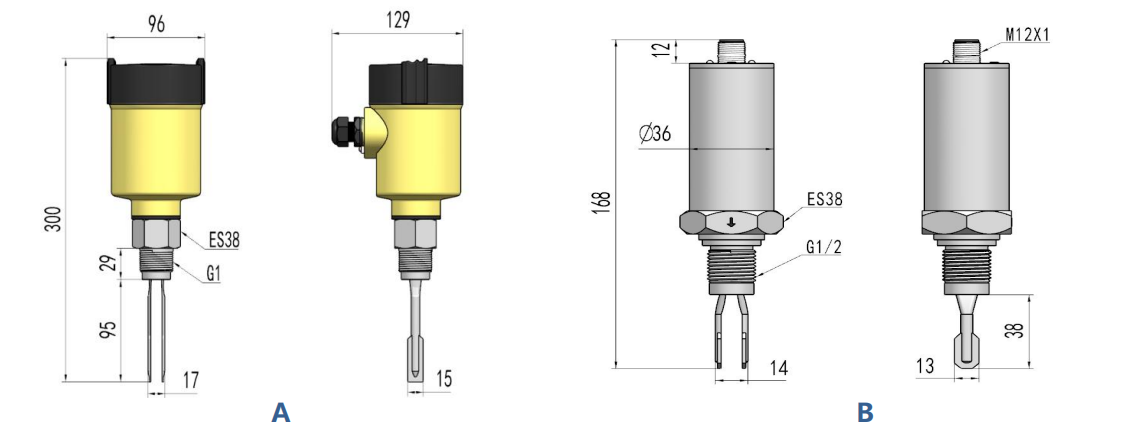

| Compact housing | ess steel 304 | ||||||

| Rugged case | Die cast aluminum | ||||||

| The fork bodys | tainless steel | ||||||

| protection class | IP65 | ||||||

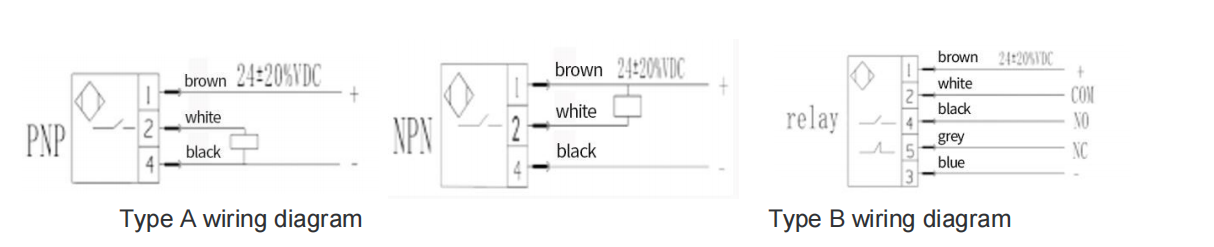

| wiring method | |||||||

| Compact housing | M12 x 1 connector | ||||||

| Rugged case | amphenol connector |

| LF100- | A | 1 | 1 | A | B | specification |

| LF100- | LF100 series tuning fork material (liquid)level switch |

|||||

| A | Rugged case | |||||

| B | Compact housing | |||||

| C | Explosion-proof enclosure | |||||

| 1 | Hersman joint | |||||

| 2 | M12×1 connector | |||||

| 3 | amphenol connector | |||||

| 1 | Power supply:24V DC | |||||

| 2 | Power supply:110V AC | |||||

| 3 | Power supply:220V AC | |||||

| A | G1 "female thread connection | |||||

| B | G1/2 male thread connection (Compact type only) |

|||||

| C | flanged joint | |||||

| A | Standard tuning fork L=40 mm | |||||

| B | Standard tuning fork L=60 mm | |||||

| C | Standard tuning fork L=100 mm | |||||

| L.. | Extended tuning fork L=mm | |||||

| *The selection table is only available for parameter selection,and the corresponding code is delivered. | ||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Tuning fork level switch-LF100 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Tuning fork level switch-LF100 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Tuning fork level switch-LF100 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .