If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Get couponsMiniature Oval Gear Flow Sensor – SN55B

Product Application:

The SN55B gear flow sensor is widely used for precise low-flow measurement in various industries.

Applicable Media:

Additives, fuels, flotation tanks in water treatment, corrosion inhibitors, catalysts, emulsifiers, oil, grease, fragrances, adhesives, solvents, ink, pesticides, and some high-viscosity fluids.

Application Industries:

Automotive, aerospace, mining, power, chemical, pharmaceutical, food, coatings, petroleum, environmental protection, printing, and more.

Especially suitable for flow measurement of high-viscosity media such as heavy oil, polyvinyl alcohol, resin (can measure fluids with viscosity up to 10,000 Pa·s).

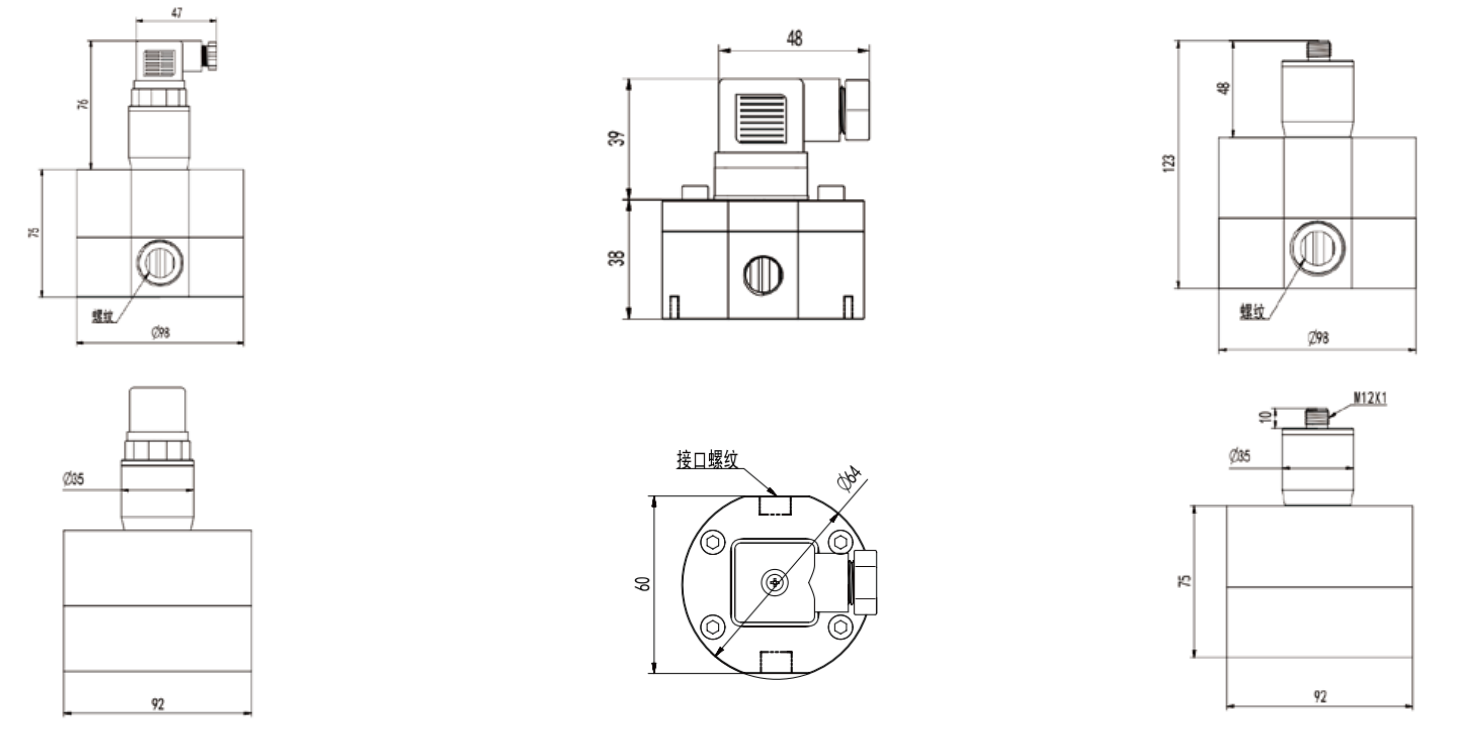

Compact and lightweight, with low vibration and noise during operation, stable performance, and capable of measuring micro-flow in small-diameter pipes.

Low starting flow, wide turndown ratio, suitable for metering liquids with large fluctuations, high accuracy unaffected by pressure or flow changes, stable performance, long lifespan, and high flow capacity.

Measurement of resin and glue

Measurement of hydraulic oil, lubricating oil, and grease

Fuel oil measurement

Measurement of liquid nitrogen, refrigerants, solvents

Measurement of edible oil, fish oil, and food filling

Chemical and anti-corrosion fluid measurement

Fluid dosing control systems

Medium temperature: -30...80℃ (high-temp customization: 150℃)

Standard pressure resistance: 5 MPa

High-pressure customization: 40 MPa (stainless steel material)

The SN55B miniature gear flow sensor features built-in dual oval gears. When fluid enters the measuring chamber, it drives the gears to rotate. The volume of liquid captured between each tooth and the chamber wall is equal.

By detecting the number of gear teeth that pass through with a specific sensor, the volume of the flowing liquid can be determined.

The SN55B gear flow sensor is not affected by the viscosity of the medium and offers high measurement accuracy and repeatability, even at the upper and lower limits of the range. It is particularly suitable for measuring high-viscosity media.

Pulse output

High pressure resistance (1.0–45 MPa)

Capable of measuring various viscous media

High accuracy and high repeatability

Wide turndown ratio (1:100)

Broad measurement range

Strong corrosion and contamination resistance (acid/alkali)

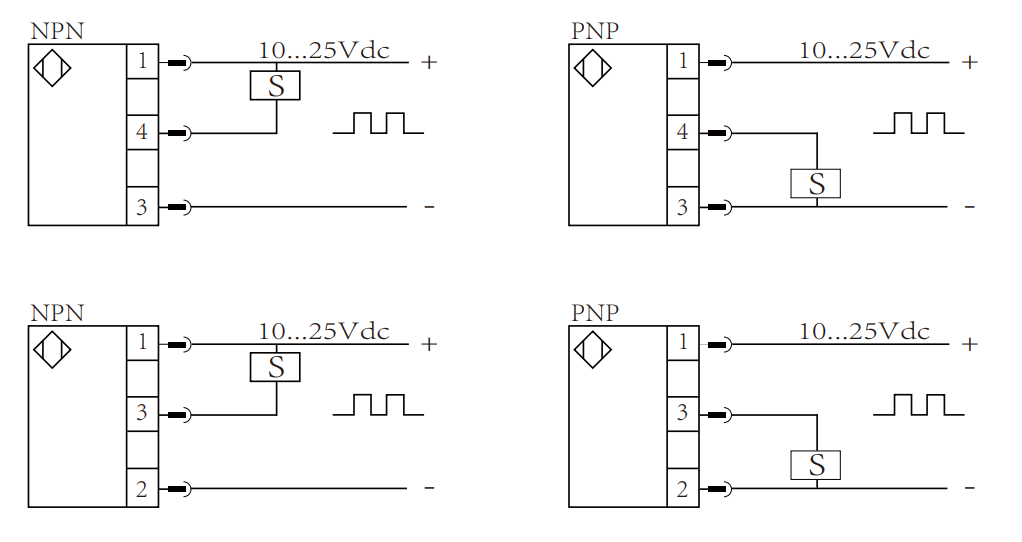

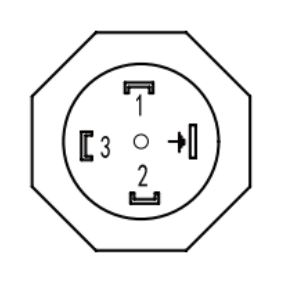

| Signal | Pin |

| Power + | 1 |

| Pulse | 3 |

|

SN55B- |

B |

A2 |

P |

X |

B |

Description |

|

SN55B- |

|

|

|

|

|

SN55B Series Miniature Oval Gear Flow Sensor |

|

|

A |

|

|

|

|

Connector |

|

|

B |

|

|

|

|

Hirschmann |

|

|

C |

|

|

|

|

Compact type (4–20 mA output only, 1–5 V output not available) |

|

|

E |

|

|

|

|

No LED display |

|

|

|

A1 |

|

|

|

Flow Range (corresponding thread): 0.003–0.8 L/min (G1/8 internal thread) |

|

|

|

A2 |

|

|

|

Flow Range (corresponding thread): 0.003–2 L/min (G1/4 internal thread) |

|

|

|

A5 |

|

|

|

Flow Range (corresponding thread): 0.004–4 L/min (G1/4 internal thread) |

|

|

|

A8 |

|

|

|

Flow Range (corresponding thread): 0.1–10 L/min (G1/4 internal thread) |

|

|

|

A8.1 |

|

|

|

Flow Range (corresponding thread): 0.01–10 L/min (G1/4 internal thread) |

|

|

|

A9 |

|

|

|

Flow Range (corresponding thread): 0.2–20 L/min (G1/2 internal thread) |

|

|

|

A9.1 |

|

|

|

Flow Range (corresponding thread): 0.02–18 L/min (G3/8 internal thread) |

|

|

|

A10 |

|

|

|

Flow Range (corresponding thread): 0.03–20 L/min (G1/2 internal thread) |

|

|

|

A15 |

|

|

|

Flow Range (corresponding thread): 0.8–80 L/min (G3/4 internal thread) |

|

|

|

A15.1 |

|

|

|

Flow Range (corresponding thread): 0.05–80 L/min (G3/4 internal thread) |

|

|

|

A20 |

|

|

|

Flow Range (corresponding thread): 0.1–120 L/min (G1 internal thread) |

|

|

|

A25 |

|

|

|

Flow Range (corresponding thread): 1–250 L/min (G1-1/4 internal thread) |

|

|

|

A30 |

|

|

|

Flow Range (corresponding thread): 2–380 L/min (G1-1/2 internal thread) |

|

|

|

|

P |

|

|

PNP pulse output |

|

|

|

|

N |

|

|

NPN pulse output |

|

|

|

|

4 |

|

|

4–20 mA output |

|

|

|

|

1 |

|

|

1–5 V output |

|

|

|

|

|

L |

|

Body Material: Alumina |

|

|

|

|

|

X |

|

Body Material: 304 Stainless Steel |

|

|

|

|

|

P |

|

Body Material: PP |

|

|

|

|

|

|

B |

Standard version |

|

|

|

|

|

|

T |

High-temperature customization |

|

|

|

|

|

|

P |

High-pressure customization |

|

The selection table is for parameter selection only. Final product is manufactured based on code corresponding to selected parameters. |

||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Miniature Oval Gear Flow Sensor – SN55B Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Miniature Oval Gear Flow Sensor – SN55B Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Miniature Oval Gear Flow Sensor – SN55B Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .