If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

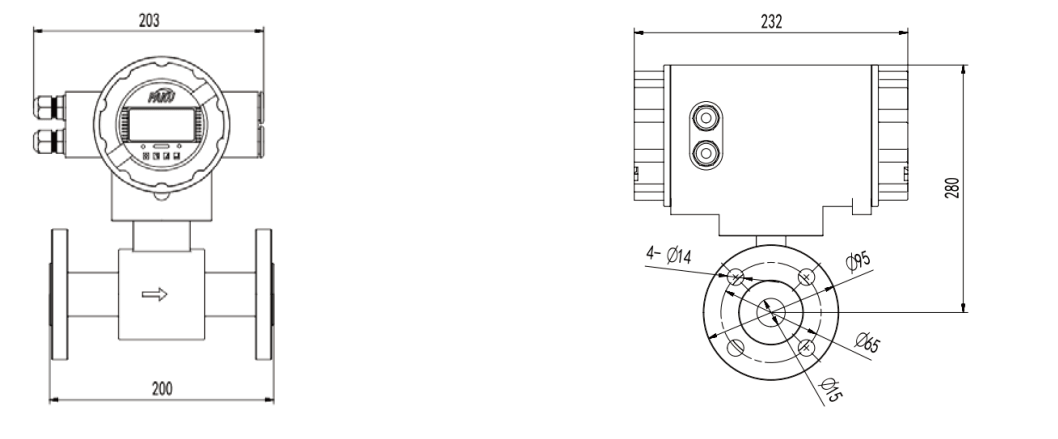

Get couponsElectromagnetic flow sensor-SN52

The SN52 series electromagnetic flowmeter is a key flow measurement instrument composed of a sensor and a transmitter. It operates based on Faraday’s law of electromagnetic induction and is used to measure conductive liquids or two-phase media. The medium’s conductivity must typically be greater than 5 µS/cm (tap water conductivity is approximately 100–500 µS/cm).

It is suitable for measuring various acidic, alkaline, and saline solutions, as well as pulp, slurry, etc. However, the medium should not contain excessive ferromagnetic substances or large amounts of bubbles.

Widely used in industries such as petroleum, chemical, metallurgy, textile, paper, environmental protection, and food, as well as in municipal utilities and water conservancy for fluid measurement.

Flow Velocity Range: 1...150 cm/s (for water)

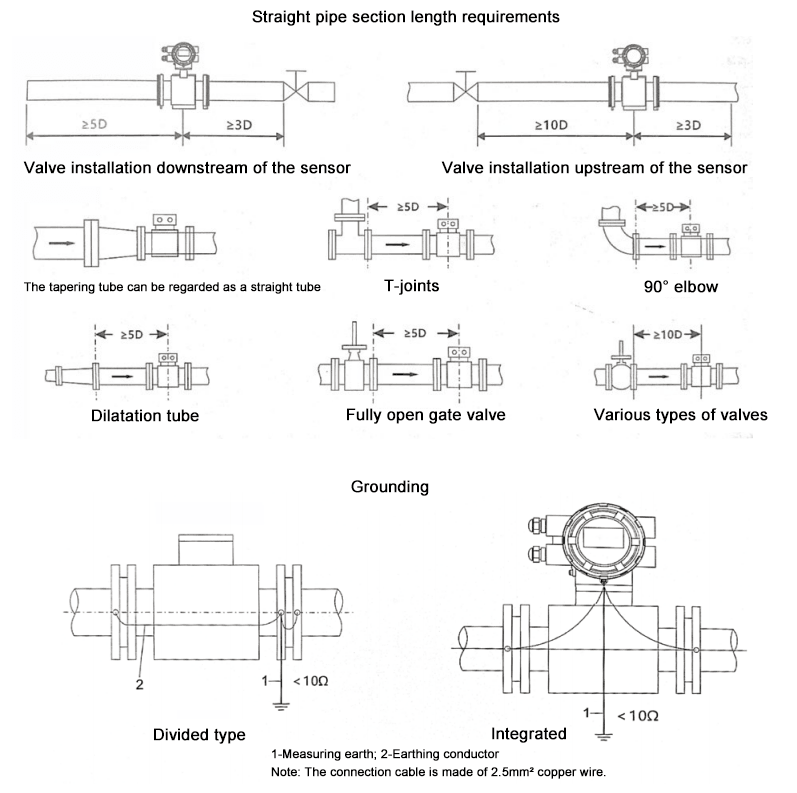

No moving parts in the measuring tube; no pressure loss; minimal straight pipe length requirement

Sensor supports grounding electrode for reliable grounding

Bi-directional flow measurement capability

Transmitter with LCD and backlight, easily readable in direct sunlight or dark environments

Transmitter can simultaneously display flow percentage, actual flow, and totalized flow

Integrated version features a ≤90° rotatable display, improving visibility after installation

Transmitter includes self-diagnostic alarms, empty pipe detection, high/low flow alarms, and dual flow outputs

| Calibre | DN10 - DN1000 |

| Measuring liquid | Conductive liquids, slurries |

| Conductivity | ≥51S/cm |

| Accuracy | ±1.0% |

| Measuring range | 1500:1 Flow rate setting: 0.1~<15m/s |

| Structure | One-piece type, split type |

| Electrode material | Stainless steel 316L, platinum iridium, Hastelloy, tantalum, titanium |

| Lining material | Gas-butadiene rubber, polytetrafluoroethylene (PTFE), polyperfluoroethylene propylene (FEP), polyurethane rubber |

| Housing material | Carbon steel (standard), stainless steel (non-standard customised) |

| Medium temperature | -40°C to + 180°C, subject to the temperature resistance of the lining material. |

| Ambient temperature | -25°C~+60°C |

| Ambient humidity | 5~100%RH (relative humidity) |

| Shell protection class | IP65, IP67, special order up to IP68 |

| Nominal diameter D( mm) |

Flow range( m³/H) | |||||

| lower limit | limit | lower limit | limit | lower limit | limit | |

| 10 | 0.08 | 3.39 | ||||

| 15 | 0.19 | 7.63 | ||||

| 20 | 0.33 | 13.56 | ||||

| 25 | 0.52 | 21.2 | ||||

| 32 | 0.86 | 34.73 | ||||

| 40 | 1.35 | 54.26 | ||||

| 50 | 2.11 | 84.78 | ||||

| 65 | 3.58 | 143.28 | ||||

| 80 | 5.24 | 217.08 | ||||

| 100 | 8.47 | 339.12 | ||||

| 125 | 13.24 | 529.88 | ||||

| 150 | 19.07 | 763.02 | ||||

| 200 | 33.9 | 1356.4 | ||||

| 250 | 52.98 | 2119.5 | ||||

| 250 | 76.3 | 3052 | ||||

| 350 | 103.85 | 4154.2 | ||||

| 400 | 135.64 | 5425.9 | ||||

| SN52- | 050 | A | A | 1 | 1 | 1 | 1 | D | 1 | 1 | Detailed description | ||||||||||

| SN52- | SN52 Series Electromagnetic Flow Sensor | ||||||||||||||||||||

| DN... | (Available in diameters DN10 - DN1000, special diameters please consult sales engineer) |

||||||||||||||||||||

| Electrodes | A | Stainless steel 316L | |||||||||||||||||||

| B | Hastelloy B | ||||||||||||||||||||

| C | Hastelloy C | ||||||||||||||||||||

| D | Platinum | ||||||||||||||||||||

| E | Titanium | ||||||||||||||||||||

| F | Tantalum | ||||||||||||||||||||

| lining material | A | Neoprene Rubber (CR) | |||||||||||||||||||

| B | Polyurethane Rubber (PU) | ||||||||||||||||||||

| C | Polytetrafluoroethylene (PTFE) | ||||||||||||||||||||

| D | Polyperfluoroethylene propylene | ||||||||||||||||||||

| Work Pressure | 1 | 4.0MPa | |||||||||||||||||||

| 2 | 1.6MPa | ||||||||||||||||||||

| 3 | 1.0MPa | ||||||||||||||||||||

| Operating temperature | 1 | ≤70℃ | |||||||||||||||||||

| 2 | ≤120℃ | ||||||||||||||||||||

| Output method | 1 | Analogue 4-20MA output, local display | |||||||||||||||||||

| 2 | Pulse output, local display | ||||||||||||||||||||

| 3 | Analogue 4-20MA output, no display | ||||||||||||||||||||

| 4 | Pulse output, no display | ||||||||||||||||||||

| Communication method | 0 | No display | |||||||||||||||||||

| 1 | RS485 communication interface | ||||||||||||||||||||

| 2 | HART protocol | ||||||||||||||||||||

| Power supply method | J | 220V | |||||||||||||||||||

| D | 24V | ||||||||||||||||||||

| C | Battery powered (no output option only) | ||||||||||||||||||||

| Protection level | 1 | IP65 | |||||||||||||||||||

| 2 | IP68 | ||||||||||||||||||||

| Converter type | 1 | Integral | |||||||||||||||||||

| 2 | Split | ||||||||||||||||||||

| * The scope of supply of electromagnetic flowmeters does not include pairing flanges, which can be manufactured by themselves or ordered separately. * The selection table is for parameter selection only, and the corresponding code is factory-delivered by the parameters. |

|||||||||||||||||||||

Technology Co., Ltd.

Shanghai Kayuan Electronic Technology Co.,Ltd is an enterprise specializing in the production and R & D of industrial sensors and controllers. Its main products include switches and sensors for flow, pressure, temperature, and liquid level. Electromagnetic flow sensor-SN52 Suppliers in China.

In 2008, our assembly plant was established in Shanghai China,PAKU INTELLIGENT EQUIPMENT(SHANGHAI)CO.,LTD a subsidiary of Kayuan to produce the PAKU series of products. As Electromagnetic flow sensor-SN52 Factory, PAKU products are now widely used in different industries, including automation complete sets of equipment, petroleum equipment, chemical equipment, power equipment, welding equipment, steel equipment, metallurgical equipment, automobiles, and water treatment. We adopt advanced technology and manufacturing processes across the board. With our professional design and production technology, comprehensive product lines, excellent quality, and sales network services, we can not only provide users with timely and professional technical support but also offer high - quality one - stop services.

We have served many customers at home and abroad, and offer Electromagnetic flow sensor-SN52 Wholesale, our products are sold to countries such as Canada, the United States, Brazil, Indonesia, Vietnam, Thailand, and Russia. We welcome extensive cooperation with OEM and ODM customers.

en

en English

English Русский

Русский España

España عرب .

عرب .