If you need any help, please feel free to contact us

If you have any further questions, please call +86-021-37566990 or fill out the inquiry form.

Product 3D Image Get couponsGas turbine flowmeter-SN57

SN57 series gas turbine flowmeter draw on the advanced concept of aviation technology and integrate the theory of fluid mechanics, electromagnetism and so on. It is a new generation of gas precision measuring instrument with high precision and high reliability, which integrates temperature, pressure, flow sensor and intelligent flow integrator.

When the inflow flow rate is timed, the flow is rectified and accelerated under the action of a special integrated rectifier for the air inlet. Since the turbine blade is at a certain Angle to the flow direction of the fluid, the turbine generates a rotational moment. After overcoming the friction moment and fluid resistance moment, the turbine starts to rotate. Within a certain flow range, the angular velocity of turbine rotation is proportional to the fluid volume flow.

According to the principle of electromagnetic induction, the use of magnetic sensor signal from coaxial rotation during induction out with fluid volume flow is proportional to the pulse signal, the signal after amplification, filtering, plastic with temperature and pressure sensor signal into micro processing unit of intelligent flow totalizer.especially for processing, and the volume of a gas flow rate and total directly display on the LCD screen.

- wide range: according to different specifications, the highest range can reach 1:226.

- High quality aluminum alloy turbine, with higher steady flow and corrosion resistance

- Imported special bearings, long service life

- The measuring room is isolated from the ventilation room to ensure the safety of the instrument

- can detect the temperature, pressure and flow of the measured gas, can automatically track and compensate the flow, and display the gas volume accumulation under the standard state (Pb= 101.325kPa,Tb=293.15K); Can query real- time temperature and pressure values

- Wide flow range (Qmax/Qmin ≥20:1), good repeatability, high accuracy (up to 1.0 level), small pressure loss, low starting flow, up to 0.6m3/h

- Multi-point nonlinear correction of intelligent instrument coefficient

- Built-in pressure and temperature sensor, high safety performance, compact structure, beautiful appearance

- meters with explosion-proof and protective functions, explosion-proof mark for Exd DEL BT4, Exia, CT4, protection grade for IP65

- The system works with low power consumption, and a 3.6V10Ah lithium battery can be used continuously for more than 1 year

- Adopt new microprocessor and high performance integrated chip, high precision, powerful function, superior performance.

- adopts the world class new technology of micro power consumption, low power consumption of the whole machine. It can be operated by internal battery for a long time, and can be operated by external power supply.

- The company can use linear correction technology, can be up to ten segments of linear correction. It can greatly provide the calculation precision of the instrument.

- The head of the flowmeter can be rotated by 350 degrees to facilitate on-site viewing of data.

- high accuracy, generally up to ± 1.5%, high accuracy up to ± 1.0%

- good repeatability, short-term repeatability can reach 0.05%r ~ 0.2%r, it is because of good repeatability, is the first choice of flow meter in trade settlement.

- According to user requirements, GPRS network gas turbine flowmeter can be provided, you can choose the built-in

GPRS or external GPRS signal acquisition box. Realize low cost, long distance wireless data transmission, can realize remote meter reading, remote monitoring of flow meter status, battery.

| Meter diameter | General: 50mm、80mm、100mm、150mm、200mm Precision: 25mm、50mm、80mm、100mm、150mm、200mm、250mm、300mm |

|||||||||||||||||||||||

| nominal pressure | 1.6Mpa, 2.5Mpa, 4.0Mpa, 6.3Mpa (higher than this pressure can be customized) | |||||||||||||||||||||||

| compensation way | Double temperature and pressure compensation | |||||||||||||||||||||||

| output signal | Pulse, 4-20mA, RS485, IC card signal | |||||||||||||||||||||||

| communication protocol |

MODBUS-RTU. HART (customize) | |||||||||||||||||||||||

| power supply | 1、External 24VDC DC power supply. Battery powered, 3.6 lithium battery. |

|||||||||||||||||||||||

| service conditions | Medium temperature: -2(TC-80°C Ambient temperature: -30°C-60°C Relative humidity: 5%-90% Atmospheric pressure: 86kPa-106kPa |

|||||||||||||||||||||||

| Protection grade | IP65、IP67 | |||||||||||||||||||||||

| anti-hazard classification |

ExdIICT6Gb | |||||||||||||||||||||||

| applicable medium | Natural gas, compressed air, nitrogen and other low flow rate gas | |||||||||||||||||||||||

| turn down | 1 : 10-1: 20 | |||||||||||||||||||||||

| precision | 1.0、1.5 | |||||||||||||||||||||||

| texture | General type: aluminum alloy. Precision type: caliber M200: aluminum alloy; Diameter 250, 300: stainless steel |

|||||||||||||||||||||||

| product standard | GB_T 21391-2008 | |||||||||||||||||||||||

| installation direction | horizontal installation | |||||||||||||||||||||||

| caliber | Flow range m³/h | caliber | Flow range m³/h | precisi | ||||||||||||||||||||

| DN25 | 5-70 (Type selection: L1) | DN150 | 50-1000 (Type selection: L5) | 1.0% 1.5% |

||||||||||||||||||||

| DN50 | (Type selection: L2) | DN200 | 100-2000(Type selection: L6) | |||||||||||||||||||||

| DN80 | (Type selection: L3) | DN250 | 200-4000(Type selection: L7) | |||||||||||||||||||||

| DN100 | 32-650(Selection: L4) | DN300 | 300-6000(Type selection: L8) | |||||||||||||||||||||

| caliber | Flow range m³/h | caliber | Flow range m³/h | precision | ||||||||||||||||||||

| DN25 | 2-20 (model selection: M1) |

DN150 | 50-1000 (model selection :M9) | |||||||||||||||||||||

| 5-70 (model selection: | 80-1600 (model selection: | |||||||||||||||||||||||

| DN50 | 6-100 (model selection: | DN200 | 80-1600 (model selection: | 1.0% 1.5% |

||||||||||||||||||||

| 10-160 (model selection: | 125-2500 (model selection: | |||||||||||||||||||||||

| DN80 | 13-250 (model selection: | DN250 | 125-2500 (model selection: | |||||||||||||||||||||

| 20-400 (model selection: | 200-4000 (model selection: | |||||||||||||||||||||||

| DN100 | 20-400 (model selection: | DN300 | 200-4000 (model selection: | |||||||||||||||||||||

| 32-650 (model selection: M8) |

320-6500 (model selection: M16) |

|||||||||||||||||||||||

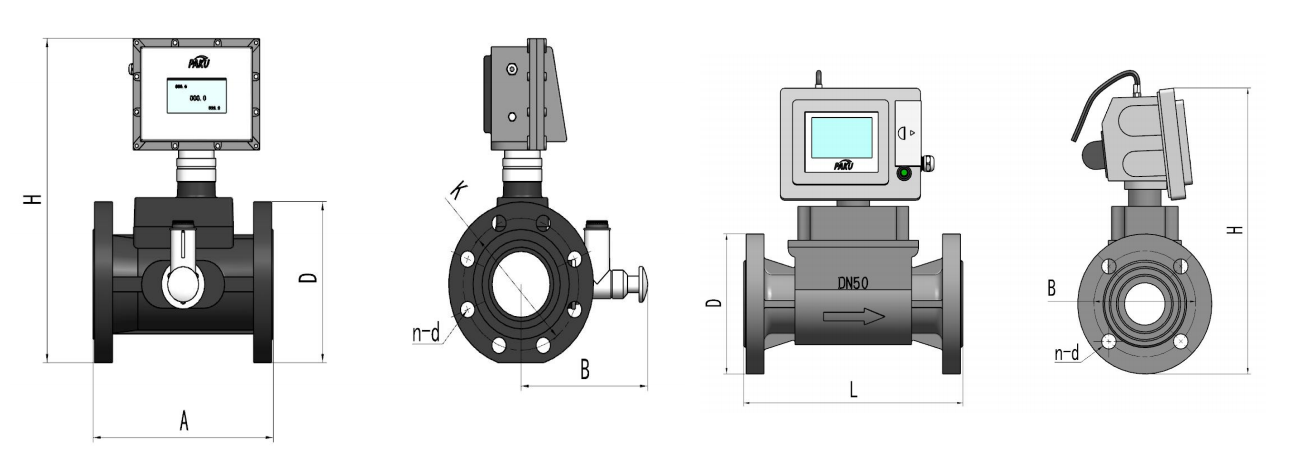

| Diameter mm |

L | B | H | K | n | d | inch | Conventional pressure MPa | |||||||||||||||

| 25 | 200 | 115 | 236 | 85 | 4 | φ 14 | M12 ×50 | 4.0 | |||||||||||||||

| 40 | 200 | 150 | 266 | 110 | 4 | φ 18 | M16 ×55 | ||||||||||||||||

| 50 | 200 | 165 | 285 | 125 | 4 | φ 18 | M16 ×60 | ||||||||||||||||

| 65 | 240 | 185 | 300 | 145 | 4 | φ 18 | M16 ×65 | 1.6 | |||||||||||||||

| 80 | 240 | 200 | 319 | 160 | 8 | φ 18 | M16 ×70 | ||||||||||||||||

| 100 | 300 | 220 | 337 | 180 | 8 | φ 18 | M16 ×80 | ||||||||||||||||

| 150 | 450 | 285 | 395 | 240 | 8 | φ22 | M20 ×80 | ||||||||||||||||

| 200 | 500 | 340 | 448 | 295 | 12 | φ22 | M20 ×90 | ||||||||||||||||

| 250 | 500 | 403 | 495 | 355 | 12 | φ26 | M24 ×90 | ||||||||||||||||

| 300 | 500 | 460 | 548 | 410 | 12 | φ26 | M24 × 100 | ||||||||||||||||

| connection type | inside nominal diameter | Conventional pressure rating |

Special pressure rating | ||||||||||||||||||||

| Flange type | stainless steel materials | DN25~ DN100 | 1.6MPA |

Below 6.3 MPA | |||||||||||||||||||

| DN150、DN200 | Below 4.0 MPA | ||||||||||||||||||||||

| DN250、DN300 | Below 2.5 MPA | ||||||||||||||||||||||

| Cast aluminium | DN25~DN150 | ---- | |||||||||||||||||||||

| Threaded connection type |

stainless steel materials | DN25、DN40、DN50 | Below 4.0 MPA | ||||||||||||||||||||

| SN57- | A | A | L1 | 4 | B4 | A | A | specification | |||||||||||||||

| SN57- | SN57 series gas turbine flowmeter | ||||||||||||||||||||||

| A | ordinary type | ||||||||||||||||||||||

| B | PD-SO | ||||||||||||||||||||||

| A | Type A: Square LCD display | ||||||||||||||||||||||

| B | Type B: circular liquid crystal display | ||||||||||||||||||||||

| C1 | Economical stand-alone version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||||||

| C2 | Precision stand-alone version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||||||

| C3 | Precision network version: IC card gas control (optional, see SN59 series for details) |

||||||||||||||||||||||

| L1 | Refer to the range table to select the appropriate range, e.g. L1 (Common) |

||||||||||||||||||||||

| M1 | Refer to the range table to select the appropriate range, e.g. M1 (precision type) |

||||||||||||||||||||||

| 4 | 4-20 ma output | ||||||||||||||||||||||

| C | pulse output | ||||||||||||||||||||||

| R | RS485 output | ||||||||||||||||||||||

| CR | Equivalent pulse output +RS485 output | ||||||||||||||||||||||

| M | MODBUS-RTU( customization ) | ||||||||||||||||||||||

| H | HART( customization ) | ||||||||||||||||||||||

| B4 | Pressure resistance: 4bar, selection B4 | ||||||||||||||||||||||

| B7 | Pressure resistance: 7bar, type B7 | ||||||||||||||||||||||

| B... | Custom compression | ||||||||||||||||||||||

| A | Accuracy: grade 1.0 | ||||||||||||||||||||||

| B | Accuracy: Level 1.5 | ||||||||||||||||||||||

| D | External 24VDC DC power supply | ||||||||||||||||||||||

| C | Battery powered, 3.6 lithium battery | ||||||||||||||||||||||

| * The selection table is only available for parameter selection, and the corresponding code is delivered. | |||||||||||||||||||||||

Technology Co., Ltd.

en

en English

English Русский

Русский España

España عرب .

عرب .